[293] Lunar flights were critically dependent on the "launch window," when trajectories of the orbiting moon and the space vehicle were compatible. Crucial slippages in preparation time were avoided during the final weeks prior to launch so that liftoff occurred during the "launch window." Schedules and deadlines extended back to the production process of rockets and their complementary equipment-a process that was nationwide and exceedingly complex. Components from thousands of contractors and subcontractors not only had to be completed on time, but all components had to arrive on schedule at one of the major centers so that units could be assembled and thoroughly checked out. The units were then shipped to Cape Kennedy for stacking on the flight vehicle. The Saturn V required 56 railroad tank cars to supply its necessary propellants. The various stages for one launch vehicle spent up to 70 days in transit at sea before arriving at Cape Kennedy, while the S-IVB and the instrument unit arrived as airborne cargoes. In the background were over 20 000 contractors and subcontractors who supplied hundreds of thousands of individual parts for the Saturn V. In 1966, Arthur Rudolph, speaking as the Director of MSFC's Saturn V Program Office, commented succinctly, "Not the least of the problems in the Saturn V system is logistics."1

Wernher von Braun, Rudolph's superior at Huntsville, pointed out two special reasons for emphasizing logistics. First, the costs of logistics might run to as much as one third of the entire launch vehicle program's budget. Any improvement, he stressed, saved money fast. Furthermore, von Braun said, logistics seemed to be taken for granted too often, and this led to troubles. By 1966, the Saturn launch vehicles had been [294] launched successfully 13 times, and good logistics was an important factor in this record of success. Still, there were occasional logistical tangles, and "there have been some awfully close calls," von Braun warned. Although the term logistics could be applied to many functions such as financial analysis and procurement, the word as used during the Saturn program applied to activities in direct support of hardware development, testing, and mission operations. This task included spares provisioning, inventory management, maintenance and maintainability, training and technical support documentation, transportation, the supply of propellants and pressurants, and the management, coordination, and evaluation of the entire process.2

In retrospect, the need for a logistical program seems logical and obvious, but it was slow to develop; the lack of such a program hampered the Saturn program for several years. When Congress passed the Space Act in 1958, the U.S. manned space program relied primarily on rocket vehicles derived from the nation's military ballistic missile programs. Despite their internal complexities, the Mercury and Gemini spacecraft were manageable under existing conditions, and the Air Force provided the requisite support functions for the launch vehicles and related logistical phases. The Apollo program changed the ground rules, because NASA intended to supply its own launch vehicles, but lack of time and money stalled the implementation of a logistical setup for the Saturn launch vehicle program.3 In the early phases of Saturn program planning, many officials felt that there was no need for military-style "launch vehicle system logistics" based on rocket weapons because NASA did not have the problems of large numbers of rockets and dispersed launch sites. Lamentably, this seemed to lead to a second assumption: since a weapon logistical system seemed inappropriate for NASA, a consensus evolved that there was no need for a logistical program at all.4 This weakness in reasoning stemmed partially from differences in the nature of the launch vehicles. NASA planned to launch a limited number of vehicles at fixed intervals and from one point, contrasted with a theoretical military situation where many launches occurred at unscheduled times from widely scattered launch sites or field positions. In a national defense situation, numbers of missiles and unanticipated circumstances required an elaborate logistical backup. Troops in the field were essentially unschooled as engineers and relied on a logistical array of technical manuals, parts, spares, and rigidly scheduled maintenance. Saturn personnel, on the other hand, included a high percentage of engineers. They did not have to rely on military procedures but could refer immediately to engineering drawings and work out an appropriate "fix" [295] on the spot, supported by conveniently accessible laboratories and machine shops at the launch site.5

The hopeful assumptions about the launch vehicles did not suffice. Factors that required logistical management included the size and complexity of vehicles, the wide geographic dispersal of launch and test sites, the pace of the program, the armies of technicians involved, and the number of suppliers around the country. "Misinterpretation then, caused neglect of an integrated logistics program," Rudolph admitted. "Thus we... created for ourselves a considerable problem by not allowing enough thought and planning toward logistics at the very outset." Theoretically, once administrators pinpointed a basic weakness in the Saturn program managerial structure, it should have been fairly economical to borrow some techniques of weapon logistics and adapt them to NASA's requirements. Comprehensive programs existed for the Minuteman and Pershing programs, but the logistics for an older, smaller rocket did not always prove adequate for a newer, larger one. As Rudolph observed, "I am not at all sure that logistic support of a launch vehicle program with its high rate of advancement in the state of technology and its associated highly complex ground support equipment is not more difficult than logistic support of a weapons system."

Further difficulties emerged as NASA management moved belatedly to establish an adequate logistical program. As problem areas became identified, additional funds to resolve the problems simply did not exist. When systems analyses indicated badly needed changes in logistics, the program manager had to take some sort of corrective action with existing funds. It came to making tradeoffs; the program manager began to rob Peter to pay Paul and sometimes found himself in a dilemma. As Rudolph phrased it, "how much of a calculated risk can he afford to take"? In 1961-1962, Saturn V managers from MSFC and personnel from the Apollo Program Office at NASA Headquarters initiated a series of "intensive, accelerated studies" to bring the logistical picture into focus. Essentially, the goal was to update the logistical organization to fit the prevailing status of vehicle development and the availability of funds. "This agonizing reappraisal lasted over many months," Rudolph recalled, "but in this way, we were able to tailor tightly, I repeat, tailor our logistical to meet the essential requirement of each stage, yet stay within budget limitations."6

Unsnarling the logistical tangle within the existing budget included the reeducation of the program managers and program personnel throughout the organization. Brigadier General Edmund F. O'Connor, Director of Industrial Operations at Marshall, emphasized the general lack of attention to logistics and misunderstandings about it in the early years. He believed that no visibility existed. "In other words," O'Connor continued, "we were having the same kind of trouble with logistics that we had with documentation, reliability, and the like. We had a serious [296] communications problem, no logistics baseline, no logistics thread running through the entire program."7

The outcome of this reevaluation was a formally organized logistical program that would keep logistical requirements up to date and that would hopefully avoid future problems. As the new plans emerged, NASA managers realized that the logistical programs of the contractors were also unclear. No one knew if contractor progress had achieved desired goals or if problems existed. Under the new regimen, Saturn V contractors began formulating logistical progress reports, and all developments were plotted against logistical control charts. In addition, each of the hardware managers acquired a logistical manager, a move that reflected the increasing concern and attention to the problem. Rudolph installed an overall logistical manager in his office to keep tabs on the lower echelons and the contractors, as well as on the MSFC laboratories in Huntsville.8

NASA's logistical management finally crystallized by 1963. Much of the push to reorganize the logistical format came from Stan Smolensky of NASA Headquarters and from Eberhard Rees, Deputy Director-Technical, in von Braun's office at MSFC. At the top of the logistical organization, NASA set up a Logistics Management Office at the staff level in the Office of Manned Space Flight (OMSF) in Washington. This new office reported directly to the Apollo Program Manager at OMSF and integrated the overall Apollo-Saturn support programs. For the Saturn launch vehicles themselves, MSFC organized a Project Logistics Office which reported to the Director of Industrial Operations. This office functioned both at a staff level and in an operational capacity, and acted in close cooperation with the respective program managers within the Saturn program as well as with the R&D laboratories at Marshall. The R&D laboratories had the technical responsibility for the development of much of the launch vehicle's systems and supporting hardware. For example, the Test Laboratory did considerable investigation of the special purpose vehicles, and the Astrionics Laboratory designated an individual to cooperate on work involving the instrument unit. Because many parts and components were being produced by the factories and the vehicles were taking shape, the project logistics office had to decide whether to repurchase or switch parts if a manufacturer decided to close down a particular operation or start up a different product line. This kind of situation meant that Marshall's personnel who were involved in the quality and reliability aspects also became part of the logistical organization. With the Project Logistics Office in operation in Huntsville, Houston's MSC relied on MSFC's growing capability for moving the command module, service module, and other large bits and pieces of spacecraft hardware around the country. As for logistical requirements emanating from the launch site in Florida, John C. Goodrum, head of [297] MSFC's Project Logistics Office, remarked that "Kennedy always considered themselves a logistics-oriented center," with internal administrative channels to handle the job, although Marshall occasionally provided transportation for KSC.9

The cooperative aspects of the logistical program included the Department of Defense, which supplied some of the propellants and pressurants for the Saturn program. Some cryogenic production plants were jointly operated under the auspices of the Department of Defense and NASA, and MSFC monitored the specifications and construction of other plants around the country. By 1965, the major plants were in operation to supply cryogenics for the rising tempo of Saturn testing and launch operations. This capability was especially important for liquid hydrogen (LH2). The space program helped raise the production levels to 190 metric tons per day, with the Saturn program absorbing up to 95 percent of the nation's total capacity. Once a plant became operative, NASA and MSFC were eager to coordinate its production with an active test and flight series, because increased LH2 consumption was a way to save money. Producers established a price for their product that was in direct relation to the volume sold. In the early 1960s, liquid hydrogen was about $20.00 per kilogram, but the price dropped to around $2.20 per kilogram for 450 kilograms, 45 to 65 cents per kilogram for 2250 kilograms, and leveled off at around 35 cents per kilogram for higher volumes. Fortunately, MSFC "never got pinned" to the $20.00 curve, Goodrum remarked, but the space agency paid some fairly high prices for liquid hydrogen from time to time. For transportation of assorted cryogenics, MSFC relied on fleets of trucks, mostly from commercial carriers; the Air Force lent occasional support.10

By 1966, Rudolph felt that the logistical problem had been controlled, and he confidently announced that the first Saturn V launch, early in 1967, would get off on schedule early in the coming year. The success in coping with the logistics of the launch cannot be underestimated. A comparison of PERT figures indicated a total of 40 000 events for the contractors working on the three stages and the instrument unit. For the ground support equipment (GSE) managers, over 60 000 events needed to be tracked. The components for ground support were manufactured throughout the United States and arrived at test sites and KSC by every conceivable means of modern transportation. Rudolph remarked that it was virtually impossible to illustrate graphically the full GSE logistical program and harder still to describe it.11

The GSE delivery requirements had many parallels in the transport logistical requirements for the various rocket stages of the Saturn program. The development of this phase of Saturn logistics also involved a transportation network from coast to coast and relied on a wide spectrum of transport equipment.

[298] Because the Saturn vehicles were originally designed for the utmost in vehicle integrity and manned missions, it would be inadvisable to degrade the integrity of Saturn components by using inferior transport modes and techniques. Rocket stages were transported thousands of miles and experienced hundreds of hours of constant vibration. There was always the possibility of damage to welded joints and seals, as well as to delicate components that were manufactured to very high tolerances. On arrival at Cape Kennedy, additional checkout tests frequently exposed a problem that could be traced to the transportation sequence. The logistics of rocket stages were not to be taken lightly.12

As early as 1959, personnel at ABMA began to study the problems of transporting boosters from the manufacturing area to the test stands and the problem of the long journey from Huntsville to the Atlantic Missile Test Range in Florida. Early proposals considered using existing transporters devised for Redstone and Jupiter missiles, but this equipment proved to be too small. To carry the larger Saturn series on Redstone-Jupiter transporters, investigators discovered they would have to disassemble and remove engines and associated equipment, then replace the engines each time the complete vehicle moved from manufacturing to testing areas. This process was repeated during shipment to the launch site. Engineers warned that such frequent reassembling would compromise the reliability of the vehicle.

As a second proposal, planners envisioned a gargantuan BARC-style amphibious vessel. The acronym came from Army nomenclature for an amphibious machine in military inventory at the time: Barge, Amphibious, Resupply, Cargo. The Army used BARCs for over-the-shore delivery of heavy tanks and other cargo, and this apparently served as the inspiration for an enormous BARC to transport Saturn rockets. This unit would pick up a Saturn vehicle at the manufacturing area, carry the vehicle to the test site and reload it after tests, and then the BARC would lumber overland and plunge into the Tennessee River. After cruising down the Tennessee and the Mississippi rivers, the ponderous BARC would churn through the Gulf of Mexico, clamber onto the Florida coast at Cape Kennedy, and move directly to the launching pads. The BARC concept was eventually scrapped. The shallow draft raised doubts about its seaworthiness in the Gulf, and its dimensions and difficult maneuverability would necessitate major modifications to existing buildings and manufacturing areas to accommodate the transporter alone. The engineers concluded that it would cost $5 000 000 and would not be operational for four years. The ABMA study recommended the construction of towable transporters for the Saturn vehicles and planned to use proven, seaworthy vessels on the waterborne leg of operations.

[299] In October 1959, the Advanced Research Projects Agency (ARPA) gave the go-ahead to the Army Ordnance Missile Command (AOMC) to begin engineering studies on the Tennessee River for dock facilities that would be conveniently accessible to the manufacturing complex at Redstone Arsenal. By December, AOMC received further authorization from ARPA not only to construct the docks but also to begin designs for a barge to carry the oversize boosters to the launch site at Cape Canaveral. The engineers decided to equip the dock areas with electrical winches for a roll-on/roll-off operation that would use the ground transporter to wheel the stage aboard the barge, ride with it to its destination, and wheel it out again. This operation promised the least strain and damage to the stage during the strenuous handling and transportation phases.13

The size of the Saturn I first-stage boosters promised some headaches when the time came to move completed stages around the manufacturing areas and between the ships and the static-firing areas of Redstone Arsenal. The Saturn engineers in Huntsville devised a solution to the problem. For the final assembly of the Saturn I first stage, workers used a pair of huge circular assembly jigs to position the cluster of one center tank and eight smaller tanks around it. These assembly fixtures at either end of the rocket then became the load-bearing structures for transportation. After the completed booster was raised with huge jacks, wheel and axle assemblies were positioned at each end. With the stage lowered onto these assemblies, they were affixed to the assembly jigs, which now became support cradles for towing the stage. The wheel assemblies, using aircraft tires, were designed for independent braking and hydraulic steering. The transporter was towed by an army truck tractor at five to eight kilometers per hour through successive phases of checkout and test. NASA also used the transporter for loading and unloading the stage from the barges that carried it from Huntsville to the launch site on Florida's east coast.14

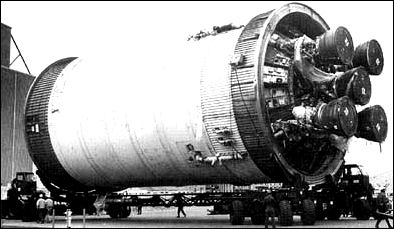

For the S-IC first stage of the Saturn V, MSFC's Test Laboratory designed a similar transporter in 1963. The S-IC transporter used a modular wheel concept, based on a two-wheel, steerable unit and clustered to comprise two dollies fore and aft-a total of 24 wheels. The wheels, similar to the 24-ply tires for earth-moving equipment, stood about as high as a man. Each modular pair of wheels incorporated a separate system for power steering, with all systems of a particular dolly interconnected by a computer to correlate the steering angles for all wheels in unison. Since the dolly units could be steered to ±90û from the axis of the transporter, the entire rig and its load could be maneuvered sideways, into, and out of checkout bays and test areas. MSFC used a modified Army M-26 tank retriever as the tractor unit for towing the S-IC and its huge transporter. The M-26, a 179-kilowatt (240&endash;horsepower) model weighing 55 metric tons, included 27 metric tons of water ballast [300] to cope with the counterweight of the transporter. The total length of the tractor and transporter unit came to about two-thirds the length of a football field and was capable of rolling along at eight kilometers per hour. In theory, the driver in the tank retriever's cab was in charge of the direction of travel, but in practice, he acted as a coordinator of a crew of other drivers and transporter personnel. When the S-IC transporter rig "hit the road," its entourage included a cluster of observers who walked along at each corner of the vehicle and alerted the driver coordinator positioned in the front of obstacles and clearances that were blocked from his view. The driver in turn relayed instructions to drivers on the transporter who were riding in cabs front and rear and who could manipulate the massive fore and aft dollies as required. Before taking on an actual stage, the entire crew trained throughout the MSFC complex on a tubular S-IC simulator that was built to the dimensions and weight of the actual stage.15

The size of the stages aboard the transporters and the combined loads they represented created some unique problems in hauling them across country. At Huntsville, highway engineers laid out a special roadway stretching 13 kilometers down to the docks on the Tennessee River. At Michoud, another Saturn roadway included the length of an old airstrip that lay between the manufacturing complex and the docking area for the barges. In California, where the Douglas and North American contractor plants were situated in urban areas, the state cooperated in granting special permits for the use of public highways for moving the S-II, S-IV, and S-IVB stages. These stages, though smaller than the S-IC, nevertheless presented special difficulties. Douglas, the....

[301] ....manufacturer of the S-IV and S-IVB stages for the Saturn I and Saturn IB, became the first major West Coast contractor to encounter such inconveniences. As the S-IV second stage of the Saturn I began to take shape in 1960, transport problems became pressing. A Douglas executive, H. L. Lambert, said that the problems of handling and transporting Saturn S-IV stages had reached the point where such considerations threatened to impose limits as a design factor.16

Each stage followed distinctive logistical patterns. After manufacture in California, the S-II traveled to the Mississippi Test Facility (MTF). The S-IC stage, manufactured at nearby Michoud, was also tested at MTF. Both stages, for all their prodigious bulk, could be transported with comparative ease via seagoing barges that used the extensive river and canal systems constructed around the Michoud and MTF facilities. After testing, barges once more carried the S-IC and S-II stages (and earlier S-I and S-IB vehicles) to Cape Kennedy. Logistical patterns for the S-IV and S-IVB were more complex. S-IVB was smaller than its companions and presented some unique handling difficulties in moving it through an especially congested area of Los Angeles to the shipping facilities. Difficulties were also encountered in loading the stages for a barge trip and delivering the stages further north and even further inland to the Douglas test facilities at Sacramento.

Customized apparatus for handling and transportation of the S-IV and IVB stages was paralleled by "customizing" the eventual routes to test and reshipment facilities. Although logic compelled logistics engineers to opt for canals and seaborne transportation instead of land transport, the overland mode still had to be used. The overland mode was the only way to move a stage from the manufacturing areas to the loading docks for the canal and seaborne segments of its journey. Douglas and NASA personnel in California began negotiations to move a 27 000-kilogram load on roads, subject to the various jurisdictions of state, county, and city. The planning and coordination took days. Fortunately, cooperation of local law enforcement organizations expedited the task, and flagmen from railroads in the area agreed to special duty when the stage and its accompanying entourage approached railroad crossings. Commercial firms that operated vans and various truck equipment, as well as local school districts with extensive bus schedules were called into consultation on the logistics of overland rockets. Because the rocket stage spread across all available lane space and the shoulders of the road, no parking space remained. Vehicles waited at roadside until the stage transporter moved by. Regular auto traffic could be rerouted, but bus lines and cartage business on normal schedules had to reroute their trips more carefully. The stage and transporter spread up as well as out, so utility companies agreed to raise (or even bury) their lines when no practical alternative routes seemed feasible. All other encumbrances along the right of way were eliminated [302] along the final route. Finally, Douglas had the responsibility to coordinate the remaining myriad travel arrangements. NASA representatives cooperated with various military personnel on sea transport, while all three elements (Douglas, NASA, and the military) kept in touch on times of arrival and departure, interior schedules, proper support equipment to load and unload the cargo, and additional problems.

Inevitably, complications arose. Early in the S-IV program, a stage enroute from Huntington Beach to Santa Monica for transfer to a barge collided with one of nature's denizens. H. E. Bauer, then a senior S-IV manager with Douglas, easily recalled the novel circumstances. It happened early in the morning, with the loaded transporter creeping at 6.4 kilometers per hour. "At that speed nothing much should happen," Bauer reminisced, "but, incredible as it may sound, we did run over a very mature and ripe skunk." By a stroke of luck, the stage itself escaped unscathed, but the transporter remained a large, odoriferous problem-"we had a 23 1/2 ft. wide, 46 1/2 ft. long, 22 000 lb. skunk on our hands." With other missions pending for the one-of-a-kind transporter, the Douglas Aircraft Company chemists who devised an effective deodorizer ranked high on the list of unsung heroes of the Saturn program.17

Ground transport of North American's S-II stage, manufactured at Seal Beach, proved to be less difficult. The Seal Beach complex was only a few kilometers from the Navy's harbor at the Seal Beach Naval Weapons Station, and a broad, four-lane highway facilitated movement of the S-II from the manufacturing area to the docks, although all local traffic had to be stopped during the operation.18

The S-IV, S-IVB, S-IC, and S-II stages acquired miscellaneous customized accessories for logistical operations, including access kits. The size of the S-IC permitted a much more elaborate panoply of tiered and balconied work platforms, installed inside and out. The S-II access equipment resembled that of the S-IV and S-IVB, a work platform which moved up and down an internal tunnel inserted through the center of both the oxidizer and fuel tanks. Movement, shipment, and accessories for the Saturn's engines relied on more conventional means. Early in the 1960s, after preliminary static tests at Edwards Air Force Base in California, F-1 engines were flown to Huntsville by the U.S. Air Force Military Air Transport Service aboard C-133B cargo planes. Beginning in 1967, the engines arrived at Michoud by truck from California, although MSFC occasionally arranged to deliver the engines by boat.19

Marshall Space Flight Center began its first important waterborne work with the Palaemon, a converted Navy barge. The vessel was about 79 meters long, with two deck levels. The Navy used the Large.....

.....Covered Lighter (YFNB) class during World War II, primarily during the Pacific campaigns, as floating supply and maintenance centers for forward operational areas. The vessels were originally designed to be self-obtained. The lower decks were divided into crew quarters, galley, machine shop, and a machine room for a pair of diesel generators to supply power. The NASA conversion essentially retained the lower deck configuration, but the top deck was removed and covered over to house the Saturn I first stage as it rested on its transporter. The structure was "beefed up" at some points, and reinforcement strips on the floor helped carry the weight of the cargo. At the forward section, the Palaemon included a different berthing arrangement for a 10-12 man crew on the upper and lower deck levels, and included the radio shack and pilot house.

To propel the barges, MSFC's Project Logistics Office relied on commercial marine contractors like the Mechling Barge Lines, Incorporated, of Joliet, Illinois. One of Mechling's tugs, the Bob Fuqua, played an especially significant role in the Saturn program, beginning with the Palaemon and the shipment of the first of the Saturn I first stages from Huntsville to Cape Canaveral. Normally, river tugboats like the Bob Fuqua pushed, rather than pulled, a string of barges. With the tug in the rear, it was easier to maneuver the barges ahead and to drop off or pick up a barge at river docks. The high pilot house on the tug made it easy to see over the string of low, broad-beamed barges and follow the channel. The Palaemon, however, featured a high, metal-canopied super-structure for the protection of Saturn stages, reminiscent of a military quonset hut set atop the barge. Because the tug captain and pilot could not see to [304] guide the barge, the Palaemon's pilot house, not the tugboat's, became the bridge for controlling the barge and tugboat while under way, although the tug continued to supply power from the rear. In emergencies, control reverted back to the tug. This remote-control procedure, unique in barging operations, was ironed out in early 1961, based on water trials on the Tennessee River using the Bob Fuqua and the Palaemon with a test booster aboard. Barge captains and pilots had to relearn control techniques and maneuvers from the forward pilot house on the barge.

The Bob Fuqua possessed other advantages. It was also a seagoing tug, and the Mechling organization operated it under seaway rights that permitted the tugboat to move the Palaemon directly from port to port-from the Tennessee docks, down the Mississippi, across the Gulf, and up the Atlantic Coast to the launch site at Cape Canaveral. After leaving the Mississippi, the barge and tug followed the Gulf Intracoastal Waterway to St. George Sound, located off the Florida panhandle; across the Gulf of Mexico to San Carlos Bay (near Ft. Myers); through the Okeechobee Waterway across Florida to Stuart, on the Atlantic Coast; then up the Florida Intracoastal Waterway to the Cape Canaveral Barge Canal. The complete voyage from Huntsville covered about 3500 kilometers and took 10 days; by using the Intracoastal Waterway, the barge and its cargo traveled only 452 kilometers in open seas, and the route kept them no more than 80 kilometers from sheltered ports along the Gulf Coast. The barge and tug entourage usually included a 12-man complement: a five-man crew from Mechling to handle the barge and tug, a half-dozen NASA personnel traveling with the stage, and one government monitor with overall responsibility for the operations. The leisurely pace of the cruise, with the amenities of a well-equipped galley, showers, and air-conditioned quarters, often attracted upper-echelon MSFC personnel, if they could find a good excuse to go along.20

The inaugural voyage of the Palaemon occurred in April 1961 when it departed from Huntsville for Cape Canaveral. Its cargo included a dummy S-IV stage for the SA-1 vehicle and a huge water-ballasted tank that simulated the size and weight of the Saturn S-1 first-stage booster. Crews at MSFC and the Cape rehearsed movements for loading, unloading, maneuvering the stage and its transporter, operating the barge. The Palaemon made the return trip in May, in time for its first operational cruise, carrying a dummy S-IV payload along with the first SA-1 flight stage that had just completed static-firing tests and final checkout at Huntsville. But on 2 June 1961, the single lock at Wheeler Dam on the Tennessee River collapsed. All river traffic halted and the Palaemon and its intended cargo were trapped upstream. The launch schedules were endangered, and NASA and MSFC scrambled to find a way to get the stage to Florida. The high national priority rating of the Saturn program and the cargo operations of the Atomic Energy Commission at Oak Ridge, Tennessee spurred prompt action. It did not take long for the [305] TVA to build roads around the collapsed lock to a point below Muscle Shoals, Alabama. But the Saturn stage still needed a barge to carry it.

The Marshall center got in touch with the Navy, and requested another suitable YFNB barge. The Navy found one in the "mothball fleet" at Pensacola and MSFC personnel went to work on its modifications. It was appropriately christened Compromise. The cargo aboard the Palaemon finally left the MSFC docks on 5 August 1961; workers unloaded the cargo at Wheeler Dam and towed the Saturn SA-1 booster and S-IV dummy stage around the locks, reloaded the booster and dummy stage aboard the Compromise, and reached the Cape on 15 August, meeting the 10-day delivery schedule. NASA pressed a different tug into service, using a tow line, and the Compromise carried its load exposed; the tight schedule did not allow time to fit the barge with the distinctive metal canopy or controls of the Palaemon. Before the end of the year, Compromise was rebuilt to more suitable specifications, complete with protective canopy and a newly outfitted pilot house in front. Prior to the reopening of the Wheeler lock in the spring of 1962, NASA authorities decided that the original sobriquet for the Compromise did not convey the proper image. The barge was recommissioned the Promise.21

For transportation of the S-IV and S-IVB from the West Coast to Huntsville and then to the Cape, NASA at first relied on ocean freighters. The larger S-II stage needed more specialized treatment, since its size did not allow it to be stored within the confines of a freighter's hold or above deck. In December 1963, NASA concluded agreements with the Military Sea Transport Service to use the Point Barrow for shipment of S-II stages from California to test and launch sites in Mississippi and Florida. The Point Barrow was a Navy LSD (Landing Ship, Dock) that had seen extensive Arctic duty before its conversion for the space program. Beginning in 1964, the Point Barrow carried some S-IVB stages as well as the larger S-II under a protective canopy located in the rear of the ship.

The other large vessels that operated for the Saturn program included the U.S.N.S. Taurus and the YFNB barge Poseidon. The Taurus, similar to the Point Barrow, carried S-IVB and S-II stages to Mississippi test locations and to Kennedy Space Center, and the Poseidon was an oversized barge built to carry the big S-IC first-stage boosters of the Saturn V between MTF, MSFC, and Cape Kennedy. The open-deck barges Little Lake and Pearl River shuttled S-IC stages directly from the factory doors at Michoud to the test stands at MTF. The barges were left uncovered because the stages were hoisted directly off the barges into position at the vertical test stands. Because neither barge had a forward pilot house, the tugs that moved them featured a second bridge perched on a framework tower rising above the original pilot house on the tug. The rig looked like a seagoing forest fire watchtower to most spectators. The remainder of MSFC's fleet was on the West Coast for S-IV and S-IVB logistics. In addition, a small flotilla of seven tanker barges was.....

[307]....stationed at MTF. These barges were designed to carry a 875 000-liter tank of liquid hydrogen and moved between New Orleans and MTF to support the S-II and S-IVB static test firings.22

William Mrazek, a top official in MSFC's Industrial Operations Division, once remarked that the Apollo program was possibly the greatest engineering program in history, overshadowing the Manhattan Project that produced the atomic bombs of World War II and outranking the efforts of the builders of the Egyptian pyramids.23 He could have added that the Apollo project depended on the existence of other massive American enterprises in engineering such as the Panama Canal and the river navigation system managed by the Tennessee Valley Authority.

After tests at Sacramento, S-IVB stages were sometimes carried by barge and freighter either directly to the Atlantic Missile Range (by way of the Panama Canal and the Gulf of Mexico), or indirectly to MSFC-a 14-day voyage up the Mississippi, Ohio, and Tennessee rivers to Huntsville for testing, and back out again. Rifle fire raised a potential hazard for the Saturn rocket stages on the Mississippi and its tributaries. MSFC and contractor authorities began to worry that the huge targets on the barges might attract young boys and their small-bore rifles. Marshall asked for a Coast Guard escort for some of the first trips, not only as protection from adolescent sharpshooters, but also from riverbank moonshiners. John Goodrum, head of MSFC's logistics office, said that he didn't remember that a barge was ever hit, but somebody once put a bullet hole in the pilot house. "That's very common on the Mississippi," Goodrum laughed. The natives were pretty good shots, and no one ever got hurt-they just decided to let you know that they were there.24

Full-sized stages for the Saturn I, Saturn IB, and Saturn V continued to move up and down the Mississippi and Tennessee rivers in the Palaemon, Promise, or Poseidon, aided by the specially rigged Bob Fuqua. Occasionally, some of the components of one of the stages had to be carried back and forth between Michoud and Huntsville for additional tests and analysis at MSFC, and these components could be lashed down as a deck load on one of the regular commercial barges that plied the rivers. Components for the S-IC stage took the water route to MSFC for testing; one cargo consisted of the 10-meter diameter intertank assembly at 6650 kilograms and 2 "Y ring" supports, 10 meters in diameter and over 6800 kilograms apiece. The average voyage of 1996 kilometers from New Orleans docks to the MSFC docks in Huntsville involved several segments and changeovers as the barge string was passed from one towboat to another. The first segment ran 1396 kilometers upriver to Cairo, Illinois, and took 10 days. At Cairo, the "rocket barge" joined a barge group under the control of an Ohio River towboat for the 76-kilometer leg to Paducah, Kentucky, the outlet of the Tennessee [308] River. The Igert Towing Company's Bill Dyer acquired control of the barge at Paducah and began the 521-kilometer run to Huntsville.

On the Tennessee River, the massive, federally supported Apollo-Saturn project took advantage of a predecessor: the Tennessee Valley Authority project. Nine multipurpose locks and dams created a navigation channel from Paducah to Knoxville, Tennessee, a span of 1014 kilometers. At an average depth of 3 meters, the river channel was quite comfortable for river barge operations. For the Bill Dyer, the first lock to lift the towboat and barge occurred just 35 kilometers from Paducah. Then followed a placid, 322-kilometer cruise at about 14 kilometers per hour as the river turned south across the western end of Tennessee, past a series of small river landings with whimsical names like Sarah's Garter and Petticoat Riffle. At Pickwick Dam, near the border of Alabama, the barge group was lifted again and turned east toward Huntsville. En route were additional locks at Wilson Dam and Wheeler Dam, elevating the Bill Dyer and its cargo a total of 77 meters within 407 kilometers of river channel. About 8 hours after emerging from the Wheeler locks the Bill Dyer put in at the MSFC boat slip, and the 521-kilometer journey on the Tennessee was completed.25

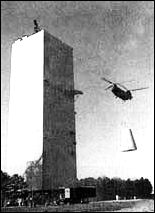

Helicopters were occasionally pressed into service to meet logistical needs for the Apollo-Saturn program. In support of vehicle dynamic tests at Huntsville, an Army CH-47A, dangling its cargo underneath flew from Tulsa, Oklahoma, to Huntsville. The Saturn IB load consisted of an adapter unit that connected the instrument unit to the service module and housed the lunar module. The tapered adapter component, 9 meters long and 6.7 meters in diameter at the base, made quite an impression as it swayed through the air during the 965-kilometer flight from North American's facility at Tulsa.26 The most impressive aerial deliveries were made by special transport aircraft that were designed to carry entire Saturn S-IV and S-IVB upper stages.

As the Saturn I program progressed, NASA officials became increasingly concerned about coordinating arrival of separate stages at the Cape to meet the launch schedules. Lower stages for the Saturn I and Saturn IB required a comparatively short voyage from Huntsville and from Michoud. Delivery of the S-IV and S-IVB from California also involved the use of seagoing barges and transports to carry these upper stages down the Pacific Coast, through the Panama Canal, across the Gulf of Mexico, and finally across Florida to Cape Canaveral. The odyssey of the S-IV and IVB stages required occasional side trips up the Mississippi and Tennessee rivers to Huntsville for additional tests at MSFC facilities before returning to the Cape. This complex and slow operation and the [309] potential delays from foul weather at sea generated increasing concern about meeting carefully coordinated deliveries of vehicle stages and related hardware. Transportation of the larger S-II second stage of the Saturn V and the S-IVB third stage from California to the Cape multiplied the concern. Another potential weak link was the Panama Canal. If the canal were to be shut down for some reason, seaborne shipments would be forced around South America and the carefully calculated launch schedules would collapse.27

Against this background, managers within NASA began thinking about other modes of transportation to ensure rapid delivery of upper Saturn stages, beginning with the S-IV. The size of the S-IV ruled out delivery to the Cape by rail or road. As the lead center of launch vehicle development, MSFC let a contract in 1960 to the Douglas Aircraft Corporation to determine the feasibility of air transport. A Douglas assessment team spent several months on the project and came up with a proposal that envisioned a "piggyback" concept that used an Air Force C-133 transport. Design studies included pictures of the rocket stage positioned above the C-133 and perched atop streamlined fairings. Because the stage was exposed to the passing airstream, planners expected to fit the stage with a streamlined nose cone, with vertical stabilizers at the rear to enhance its aerodynamic qualities in transit. Suggestions from other sources ran the gamut from airplanes to gliders to lighter-than-air vehicles. One proposal envisioned the use of a blimp, which would putter along from California to Florida with a swaying S-IV stage slung underneath. As late as 1963 serious thought was given to resurrecting a modern successor to the prewar dirigible, with an interior cargo hold to carry rocket stages.28

The Douglas organization already possessed its own reservoir of experience in the transportation of rockets by aircraft. The Douglas Thor IRBM had been freighted regularly on transcontinental and intercontinental flights by Douglas C-124 Globemasters, and the company was confident that this mode of transport was practical because its own aerial operations had not damaged any rocket or its systems. The Thor, however, had been designed for airborne shipment,29 and the situation was now reversed. Douglas was ready to listen when approached with an unusual scheme: the modification of an existing aircraft to completely enclose the rocket stage with an airplane's fuselage.

The idea of a bloated cargo airplane originated with an imaginative group associated with John M. Conroy, aerial entrepreneur of an outfit aptly named Aero Spacelines, Incorporated, in Van Nuys, California. Aero Spacelines intended to acquire surplus Boeing B-377 Stratocruisers. About 1960, Conroy and some partners acquired title to over a dozen four-engined airliners, used mainly by Pan Am and Northwest Orient on their intercontinental routes during the Stratocruiser's heyday in the 1950s. The Conroy group at first planned to use the planes for [310] nonscheduled air carry operations, but airlift for Air Force rockets also looked promising. By 1961, plans had progressed to fly NASA's new family of large launch vehicles.30

Drawing heavily on his own financial resources, Conroy pushed the idea of his bulbous, "volumetric" airplane despite the considered opinion of many aircraft engineers and aerodynamicists that no plane could be distorted and distended enough to swallow an S-IV rocket stage and still be able to fly. But Conroy was persuasive. R. W. Prentice, who managed the S-IV logistics program at Douglas, remembered him as real "swashbuckler," the sort of aviation character that reminded him of the cartoon hero named "Smilin'Jack." Conroy apparently found some kindred souls among influential Douglas executives, because he persuaded the company to go along with him on a presentation to NASA and MSFC. Some of the NASA managers were unconvinced, but the energetic Conroy touched a responsive chord in MSFC's visionary director, Dr. Wernher von Braun. As John Goodrum, chief of MSFC's logistics office, recalled the sequence of events, von Braun warmed to the idea from the start. The idea was innovative and its boldness appealed to him. Neither MSFC nor NASA Headquarters could allocate substantial funds to such a project at the time. Nevertheless, buoyed by the interest evinced at both Douglas and MSFC, Conroy decided to plunge ahead, although there was no guarantee of a contract.31

The first phase of the project called for lengthening the fuselage (by inserting the cabin section of another Stratocruiser) to accommodate the S-IV stage. After the flight test of that modification, phase two called for the enlargement of the plane's cabin section to approximately double its normal volume. The swollen, humpbacked addition to the original Boeing airframe was originally fabricated as a nonstructural element stuck on the top of the fuselage. This alteration allowed test pilots and engineers to conduct flight tests and analyze the altered flying characteristics in comparative safety. The first flight occurred on 19 September 1962, followed by more than 50 hours of cross-country trials and other experimental flights. Satisfied that the reconfigured aircraft could indeed fly, workmen finally cut away the original inner fuselage and the massive external shell was mated to the basic airframe as a load-bearing structure. The name Aero Spacelines selected for its unique plane was a natural. The former Stratocruiser became a B-377 PG: the Pregnant Guppy. The new plane had cost over $1 000 000.32

The Guppy's designers intended to make the plane a self-contained cargo transportation system. The fuselage separated just aft of the wing's trailing edge to load and unload the S-IV and other cargoes. The ground crew unloaded and attached three portable dollies to the rear part of the plane and disengaged the various lines, cables, and bolts connecting the fuselage sections. The rear portion was then rolled back to expose the plane's cavernous hold.33

[311] In the course of work on the Guppy, Conroy began running out of cash and credit. He figured he needed some tangible support from NASA in the form of an endorsement to keep his creditors at arm's length. On 20 September 1962, only one day after the first air trials of the reconfigured prototype cargo version, Conroy and an adventuresome flight crew took off for a demonstration tour. At this stage of the plane's development, the B-377's original fuselage was still intact, and the massive hump attached to the outside was held up by an interior framework of metal stringers and wooden two-by-fours. Conroy had to get a special clearance from the Federal Aviation Administration which allowed him to proceed eastward from Van Nuys, as long as he avoided major population areas en route. Following several interim stops, the Pregnant Guppy flew to Huntsville, where Conroy wanted to demonstrate the plane to MSFC officials and perhaps get some form of unofficial encouragement to enable him to continue the plane's development.

He landed at the airstrip of the Army's Redstone Arsenal, a facility shared jointly by MSFC and the Army. The Guppy was visited by a mixed group of scoffers and enthusiasts, including von Braun. While some onlookers made sour jokes about the reputed ability of the awkward-looking plane to fly Saturn rocket stages from the Pacific to the Atlantic coast, von Braun was delighted. With both time and money in short supply, Conroy wanted to pull off a convincing test of the Guppy's ability to fly a heavy load. Because there was no time to install enough sandbags in the hold to simulate the proposed cargo capacity, the plane was completely gassed up with a load of aviation fuel to make up the weight difference. MSFC's logistics chief, John Goodrum, observed the proceedings, and most of the people around him seemed very doubtful of the plane's potential. "In fact," remembered Goodrum, "there were some pretty high ranking people who stood right there and shook their heads and said it just wouldn't fly-there is no way!"

With Conroy at the controls, the big plane lumbered down the runway and into the air. The pair of MSFC observers aboard this first flight included Julian Hamilton, a key manager in Saturn logistics programs, and Herman Kroeger, a member of the von Braun group since the V-2 program in Germany and a former test pilot. Even with the number one and two engines out, the plane could maintain course and altitude with only light control. This feat so impressed ex-test pilot Kroeger that he lapsed into German in describing it to his colleagues after the plane landed. Von Braun was so interested that he wanted to fly in the airplane. The MSFC director crawled in the airplane and took off, to the consternation of those still dubious about the airworthiness of the fuel-heavy airplane braced on the inside by a wooden framework. The flight was uneventful, and informal contract talks began the same day. There was little doubt that Conroy needed some firm support. His [312] finances were in such bad shape that he reached Huntsville only by borrowing some aviation gas from a friend in Oklahoma, and MSFC agreed to supply him with enough gas to fly home to California.34

Conroy was able to supply information for more serious contract negotiations by late fall of 1962. Conroy reported in a letter to von Braun that performance of the Pregnant Guppy guaranteed cruising speed in excess of 378 kilometers per hour. The correspondence also revealed the growing extent of MSFC cooperation and support for the proposed Guppy operations involving cooperation from military bases, although no official contracts had been signed. Aero Spacelines planned to keep critical spares at strategic locations along its route structure to reduce downtime in case of malfunctions. This arrangement included the special allocation of a "quick-engine-change" unit at Patrick AFB, Florida, near the launching sites of Cape Canaveral. NASA also planned to arrange for Aero Spacelines to purchase supplies of fuel and oil at the military bases along the Guppy's route.35

In the spring of 1963, the space agency was planning the first two-stage launch of the Saturn I vehicle, designated SA-5. The first four launches had carried inert second stages, and SA-5 had special significance as the first of the giant Saturn boosters to have both stages "live" and operational. The agency was growing anxious over the delivery of the S-IV-5 stage because of a time slippage caused by test problems, and the Pregnant Guppy would save considerable time by flying the stage from California to the Cape in 18 hours, as opposed to 18-21 days via ship. In a letter dated 25 April 1963, NASA's Director of Manned Space Flight, D. Brainerd Holmes, emphasized the Guppy's importance to Associate Administrator Robert Seamans. Holmes wanted to make sure that the FAA was "advised of NASA's vital interest" in securing the Pregnant Guppy's prompt certification so that lost time could be made up in the delivery of the S-IV-5 stage. Holmes pointed out that NASA had also made several telephone calls to FAA officials.36

As evidence of NASA's growing commitment to Guppy operations, Aero Spacelines was finally awarded a contract from MSFC, to cover the period from 28 May-31 July 1963, to complete the plane's tests and make an evaluation as soon as possible. The FAA awarded the B-377 PG an airworthiness certificate on 10 July, and MSFC immediately conducted a transcontinental trial flight with a simulated S-IV stage aboard. Although the Pregnant Guppy did not receive its final certification as a transport craft until 13 November 1963, NASA relied on the plane to carry Apollo spacecraft hardware to Houston during the late summer months, and in mid-September the Pregnant Guppy took on the S-IV-5 stage at Sacramento for delivery to Cape Kennedy for the launch of SA-5. Technical problems in the first stage delayed the launch for many weeks, but the two-stage rocket finally made a successful flight on 29 January 1964.37

[313] The Guppy saved up to three weeks in transit time and effected substantial savings in transportation costs, and won endorsements and long-term contracts from NASA officials. The plane was operated by MSFC but carried a variety of NASA freight including launch vehicles for the Gemini program, Apollo command and service modules, hardware for the Pegasus meteoroid detection satellite, F-1 engines, the instrument unit for Saturn I, and "other general outsized NASA cargo."38

For these reasons, as well as NASA's concern for the larger space hardware in the Saturn IB and V programs, NASA managers expressed interest in correspondingly larger aircraft. Because the S-IVB stage was larger than the S-IV, it would require a larger plane if air operations were to be continued. A larger plane could carry the instrument unit for both the Saturn IB and the Saturn V as well as the Apollo lunar module adapter unit. Moreover, a second plane could serve as a backup for the original Guppy. At one point in the discussions about a second-generation aircraft, serious consideration was given to the conversion of an air transport large enough to handle the S-II second stage of the Saturn V.

Even before the Pregnant Guppy had won its first NASA contract, Conroy was writing to von Braun about a successor aircraft equipped with powerful turboprop engines and large enough to transport the S-IVB. NASA did not seriously consider the second-generation Guppy until the original Pregnant Guppy had demonstrated its worth. Robert Freitag, NASA Headquarters' Director, Manned Space Flight Center Development, wrote von Braun in early 1964 noting the "outstanding success we have enjoyed with the Pregnant Guppy." In addition to the Pregnant Guppy's use by MSFC to carry rocket stages, Freitag said the Manned Spacecraft Center in Houston was anxious about having a backup aircraft available. Freitag envisioned three possibilities: acquire a similar Pregnant Guppy and rely on water transport for the S-IVB and S-II stages, acquire a larger type for S-IVB operations and leave the S-II to water transport, and acquire an S-II-size aircraft that could also handle the smaller S-IVB. Any of the three possibilities could meet the logistical requirements of the Houston center, but a decision was needed soon; the timing for production and delivery of Saturn rocket stages to the Cape to meet launch schedules was in question. "Since time is of the essence, Freitag concluded, "I would appreciate receiving your recommendations including advantages and technical funding plan for accomplishing our objectives at the earliest possible date."39

Evidence suggests that MSFC gave serious thought to a mammoth aircraft capable of handling a rocket stage the size of the S-II. On 2 February 1964, MSFC drafted a request for quotation titled "Large Booster Carrier Aircraft." The document suggested the development of either an airplane or a lighter-than-air vehicle capable of transporting the [314] S-II (or S-IVB) to test sites in southern Mississippi and the Cape. "In any case, the program is to be characterized by austere funding and early delivery schedules." Several companies proposed various schemes, including the use of modified B-36 bombers or English-built Saunders-Roe Princess flying boats.40 None of these plans ever materialized. NASA concluded that an S-II cargo aircraft would take too long to develop and would cost too much. Also the number of planned Saturn V launches was revised downward, reducing the requirements for S-II transportation. The S-IVB, however, was programmed for frequent launches in both the Saturn IB and Saturn V class of vehicles, so the desire for a backup airplane persisted.41 With its Boeing Stratocruiser inventory, Aero Spacelines proved to be ahead of any competition in supplying a second volumetric air transport.

As before, Aero Spacelines developed the new aircraft with its own resources, although personnel from MSFC came to California to cooperate on the design studies, and a flight-test expert from NASA's Flight Research Center at Edwards, California, worked very closely with the design team. Originally dubbed the B-377 (VPG) for "Very Pregnant Guppy," the second-generation plane finally emerged as the "Super Guppy," or B-377 SG. The larger, heavier cargoes for the Super Guppy required increased horsepower. Although parts of three other B-377 aircraft were incorporated into the Super Guppy, the cockpit, forward fuselage and wing sections, and the engines came from a Boeing C-97J, an Air Force transport version of the commercial Stratocruiser. This aircraft had Pratt & Whitney turboprop engines. Conroy realized that it was imperative for his big new airplane to have the more efficient and powerful turboprop powerplants. Conroy had learned from his contacts in the Air Force that the C-97J airplanes were headed for retirement, and he had hoped to get the airframes as salvage and the engines on a low-priced lease. Conroy succeeded, with NASA lending special assistance in securing the engines. During the spring of 1965, NASA's Office of the Administrator made overtures to the Air Force: "We definitely feel that it would be in the public interest and advantageous to the government if these engines were made available" to transport rocket stages, engines, and other large cargoes. "Under these circumstances," NASA explained, "we would appreciate it if you would approve the proposed lease."42 Conroy got his engines, and the Super Guppy began acceptance tests before the year was out.

NASA wanted to put the aircraft in service early in 1966, after the plane had proved its flying capabilities, although final FAA certification came later in the spring. John C. Goodrum, chief of MSFC's Project Logistics Office, felt that the utility of the Super Guppy was of such importance that it should be considered operational for "critical cargoes" on a "limited basis" as soon as possible. Although FAA examiners had not yet flown the Super Guppy by March, Goodrum urged operational [315] service based on the judgment of NASA's own test pilots at Edwards that the plane was satisfactory for transport duties. He advised NASA Headquarters that MSFC planned "immediate utilization" of the airplane to ship a Saturn instrument unit manufactured by IBM in Huntsville. The Super Guppy landed at Huntsville within a week, apparently by special arrangement with the FAA, and flew the IU to the Douglas plant at Huntington Beach for systems testing with an S-IVB stage. The plane made a return trip before the end of the month and delivered another S-IVB test stage to MSFC.43

As the Super Guppy became fully operational during 1966, its success reflected the expertise accumulated in missions using its predecessor. The Super Guppy's cargo was loaded from the front, and the entire forward section of the fuselage was built to swing aside on hinges just ahead of the wing's leading edge. This modification added to the ease and swiftness of its operations, and was largely dependent on the ground support techniques and equipment developed for the Pregnant Guppy in the early 1960s. After modification, equipment designed for the S-IV served equally well for the larger S-IVB. The cargo lift trailer (CLT) became a major item in the support equipment developed for handling space hardware as air cargo. The CLT was developed at MSFC and operated on the scissor-lift principle to raise its load for transfer into the cargo hold of the airplane. The CLT could also be used as a transporter over short distances. A movable pallet supported the S-IV on the CLT. The pallet had cradle supports fore and aft that were linked to the pallet with shock mounts of an oil-spring type. The CLT raised the pallet to the loading level of the cargo bay, then the pallet was rolled off and secured inside the aircraft. For aerial shipment, ground crews did not use the shroud that protected the rocket stage during water transport. Instead, engineers designed lightweight covers to fit over the exposed areas fore and aft, and a bank of static desiccators in the propellant tanks comprised the environmental control system while airborne. Both Guppy aircraft carried the instrumentation to monitor pressure, humidity, temperature, and vibration readings in flight as part of the plane's permanent equipment. In a typical delivery sequence, the rocket stage moved eight kilometers overland from the Douglas plant at Huntington Beach to the Los Alamitos Naval Air Station. After loading the stage, the pilots flew north to Mather Air Base, not far from SACTO. When stage tests were completed, the final leg of the airborne logistics sequence concluded with delivery at Cape Kennedy for preflight checkout and launch.44

Although no stage damage occurred during the aerial delivery by the Guppies, the planes occasionally experienced some troubles, and some delivery schedules were affected by adverse weather. The Guppies might make three or four stops between California and Florida, depending on the winds aloft and weather en route. Aero Spacelines relied on a....

|

.

|

|

|

. |

|

|

| ||

|

. |

|

|

|

|

.

|

|

[317]....string of selected SAC bases and other Air Force fields for fuel and operational support, and these installations were normally alerted ahead of time for the appearance of the strange-looking Guppy in the landing pattern. Not long after the start of Pregnant Guppy flights, a misadventure occurred, and NASA's S-IV rocket stage was temporarily impounded by Air Force security personnel. Don Stewart, who represented MSFC as a monitor for the early operational flights, recalled that the Guppy pilot had been forced off his normal route out of Los Angeles to avoid bad weather, and the plane had begun to run low on gas. Both Stewart and the pilot thought their alternate field, a SAC base, had been notified of Guppy operations. They were mistaken. After a night landing, the plane was surrounded by SAC security police brandishing carbines and M-1 rifles. The SAC guardsmen were caught off balance by the large and unusual aircraft that carried a rocket, and they directed the plane to a remote corner of the airfield until the intruder's credentials could be verified. The Guppy crew dozed fitfully in the plane until the base commander was convinced of Stewart's story, checked with the proper authorities, and finally issued a clearance to refuel and take off in the early hours of the morning.45

In flight, the Pregnant Guppy behaved normally, although Air Force and NASA ground crews had to learn to cope with some of its unusual idiosyncracies on the ground. During a stop at Ellington Air Force Base at Houston, high winds swept into the vast hold of the detached aft section, and caused light damage to the plane's tail. After a couple of mishaps involving the Super Guppy, designers beefed up the massive dome and redesigned the latching mechanisms on the hinged nose section. The Super Guppy experienced occasional engine problems, and NASA wisely kept the plane on the ground during high winds.46

Despite these occasional incidents, the ungainly looking airplanes routinely performed their duties week after week, and flew one-of-a-kind, multimillion dollar cargoes between NASA facilities, contractor plants, and the launch site at Cape Kennedy. The Guppies transported other diversified cargoes in addition to rocket stages and engines. During 1968, the Super Guppy carried the special environmental chamber used for final preparation of the manned Apollo command module prior to launch, as well as carrying cryogenic tanks for an experimental nuclear rocket. As the Skylab orbital workshop progressed in the late 1960s and early 1970s, the Guppies ferried such components as the multiple docking adapter, the Apollo telescope mount, and the Skylab workshop itself (adapted from the S-IVB).47 The success of Aero Spacelines and its original Pregnant Guppy attracted the attention of other firms with thoughts of diversification, and in July 1965 the company was acquired by the Unexcelled Chemical Corporation. The new organization not only proceeded with the Super Guppy configuration; it also constructed a [318] small fleet of volumetric aircraft to haul outsized cargoes such as large aircraft sections, jet engines, helicopters, oil drilling equipment, and boats for NASA as well as for the Air Force and commercial firms.48

Although the cargoes carried by the Guppies were limited in number, they were unique and of considerable importance. In the opinion of John Goodrum, head of MSFC logistics, the payoff of the Guppy operations was exceptional for NASA, especially during the 1966-1967 period, when closely scheduled Saturn IB and Saturn V launches put a high premium on rapid aerial deliveries of S-IVB stages and instrument unit components to Cape Kennedy. It would be too strong to say that the Guppy operations saved the Saturn program, Goodrum said reflectively, but without the availability of the unique planes, NASA might have been forced to scrub some of the scheduled launches and might have incurred horrendous costs in money and time.49

The Guppy shipments of outsize components such as jet engines and wing sections offered a unique and highly valuable mode of transport in terms of commercial operations. The Guppies carried a limited number of otherwise awkward and critical items in situations where the saving of time was paramount. Nowhere was this capability more evident than in the nation's Apollo-Saturn program.

Logistics were not thoroughly analyzed at the start of the Apollo-Saturn program. The logistical requirements of Saturn parts, spares, and propellants, including the delivery of large rocket stages from the West Coast to the East Coast, took considerable manpower and unanticipated planning time. The dimensions of the stages required custom-built transporters, customized inspection equipment, and other accessories. Logistics managers learned to allot plenty of time for the planning and coordination that was necessary to move Saturn rocket stages over public roadways.

The extent of NASA's water and air operations was little known to the general public. The water routes encompassed passage through both the Pacific and the Atlantic oceans, and required negotiation of the Panama Canal, the Gulf of Mexico, and the Intracoastal Waterway. The waterborne routes were time-consuming, but remained the only feasible mode of transporting the largest of the Saturn stages. Saturn transportation also relied on inland waters for transportation between the Gulf Coast and Huntsville; logistics managers took advantage of canals and other waterways for the transfer of the S-IC and S-II stages from the manufacturing center at Michoud and from test areas at the Mississippi Test Facility. The airborne operations represented the imagination and ingenuity of the Saturn program. The Guppy aircraft made an invaluable....

![The Navy assisted NASA with water transportation of Saturn stages.[link to a larger picture]](p319as.jpg)

![SATURN TRANSPORTATION EQUIPMENT. [link to a larger picture]](p319bs.jpg)

....contribution to the maintenance of schedules, which held the line on costs.

NASA and MSFC implementation of a logistics plan was an essential factor in meeting deadlines, especially for rocket launches. Stages reached Kennedy Space Center on schedule, and NASA's program for a lunar landing before the 1970s stayed close to its timetable.