Part 1 (B)

Defining Contractural Relations

January 1963 through March 1963

1963

January

1963

February

1963

March

January 2

MSC awarded a $3.69 million contract to the Radio Corporation

of America

A drawing of the larger chamber, including the position of simulated

solar sources.

RCA Service Company to design and build two vacuum chambers at MSC. The

facility was used in astronaut training and spacecraft environmental testing.

using carbon arc: lamps, the chambers simulated the sun's intensity, permitting

observation of the effects of solar heating encountered on a lunar mission. At

the end of July, MSC awarded RCA another contract (worth $3,341,750) for these

solar simulators.

MSC Release 63-1, "Contract Awarded to RCA Services Company" [January 2,

1963]; MSC, "Consolidated Activity Report for the Office of the Director, Manned

Space Flight, July 21-August 17, 1963," p. 3.

January 8

After studying the present radar coverage provided by ground

stations for representative Apollo trajectories, North American recommended that

existing C-band radars be modified to increase ranging limits. The current

capability for tracking to 920 kilometers (500 nautical miles), while

satisfactory for near-earth trajectories, was wholly inadequate for later Apollo

missions. Tracking capability should be extended to 59,000 kilometers (32,000

nautical miles), North American said; and to improve tracking accuracy,

transmitter power and receiver sensitivity should be increased.

Memorandum, C. H. Feltz, NAA, to MSC, Attn: J. T. Markley, "Contract No. NAS

9-150, Research and Development for Project Apollo Spacecraft, C-Band Coverage

Preliminary Report," January 8, 1963.

January 8

Joseph F. Shea, Director of the Office of Systems in NASA's

Office of Manned Space Flight (OMSF), briefed MSC officials on the nature and

scope of NASA's contract with Bellcomm for systems engineering support. Also,

Shea familiarized them with the organization and operation of the Office of

Systems vis-a-vis Bellcomm. [Bellcomm, a separate corporation formed by American

Telephone and Telegraph and Western Electric early in 1962, specifically at

NASA's request, furnished engineering support to the overall Apollo program.]

Bellcomm's studies, either in progress or planned, included computer support,

environmental hazards, mission safety and reliability, communications and

tracking, trajectory analyses, and lunar surface vehicles.

Memorandum, Paul E. Purser, MSC, to Distribution, "Operations of OMSF Office

of Systems and Bellcomm," January 14, 1963.

January 10

MSC and OMSF agreed that an unmanned Apollo spacecraft must

be flown on the Saturn C-1 before a manned flight. SA-10 was scheduled to be the

unmanned flight and SA-111, the first manned mission.

Memorandum, John H. Disher, NASA, to MSC, Attn: Paul E. Purser, "Review of

Apollo Quarterly Status Report No. 2," January 23, 1963.

January 16

The MSC Flight Operations Division's Mission Analysis Branch

analyzed three operational procedures for the first phase of descent from lunar

orbit:

- The first was a LEM-only maneuver. The LEM would transfer to an orbit

different from that of the CSM but with the same period and having a

pericynthion of 15,240 meters (50,000 feet). After one orbit and

reconnaissance of the landing site, the LEM would begin descent maneuvers.

- The second method required the entire spacecraft (CSM/LEM) to transfer

from the initial circular orbit to an elliptical orbit with a pericynthion of

15,240 meters (50,000 feet).

- The third technique involved the LEM's changing from the original

147-kilometer (80-nautical-mile) circular orbit to an elliptic orbit having a

pericynthion of 15,240 meters (50,000 feet). The CSM, in turn, would transfer

to an elliptic orbit with a pericynthion of 65 kilometers (30 nautical miles).

This would enable the CSM to keep the LEM under observation until the LEM

began its descent to the lunar surface.

Comparisons of velocity changes

and fuel requirements for the three methods showed that the second technique

would use much more fuel than the others and, therefore, was not recommended for

further consideration.

[Apocynthion and pericynthion are the high and low points, respectively, of

an object in orbit around the moon (as, for example, a spacecraft sent from

earth). Apolune and perilune also refer to these orbital parameters, but these

latter two words apply specifically to an object launched from the moon itself.]

Memorandum, Stephen Huzar, MSC, to Chief, BOD, "Comparison of Fuel

Requirements for Three Near-Moon Orbital Techniques Associated With the Planning

of the Lunar Landing Mission," January 16, 1963.

January 16-February 15

North American awarded Airborne Instruments

Laboratory, a division of Cutler-Hammer, Inc., a contract for the CM recovery

antenna system. NAA,

"Apollo Monthly Progress Report," SID 62-300-10, March 1, 1963, p. 3.

January 16-February 15

Representatives of North American, Langley

Research Center, Ames Research Center, and MSC discussed CM reentry heating

rates. They agreed on estimates of heating on the CM blunt face, which absorbed

the brunt of reentry, but afterbody heating rates were not as clearly defined.

North American was studying Project Mercury flight data and recent Apollo wind

tunnel tests to arrive at revised estimates.

"Apollo Quarterly Status Report No. 3," p. 33; "Apollo Monthly Progress

Report," SID 62-300-10, p. 7.

January 17

Christopher C. Kraft, Jr., of MSC's Flight Operations

Division (FOD), advised ASPO that the digital up-data link being developed for

the Gemini program appeared acceptable for Apollo as well. In late October 1962,

representatives of FOD and ASPO had agreed that an independent up-data link a

means by which the ground could feed current information to the spacecraft's

computer during a mission was essential for manned Apollo flights. Kraft

proposed that the Gemini-type link be used for Apollo as well, and on June 13

MSC ordered North American to include the device in the CM.

Memorandum, Christopher C. Kraft, Jr., MSC, to Mgr., ASPO, "Apollo Up-Data

Link," January 17, 1963; letter, H. P. Yschek, MSC, to NAA, Space and

Information Systems Div., "Contract Change Authorization No. Fifty-Four," June

13, 1963.

January 17

President John F. Kennedy sent his budget request for Fiscal

Year 1964 to Congress. The President recommended a NASA appropriation of $5.712

billion, $3.193 billion of which was for manned space flight. Apollo received a

dramatic increase - $1.207 billion compared with $435 million the previous year.

NASA Administrator James E. Webb nonetheless characterized the budget, about

half a billion dollars less than earlier considered, as one of "austerity."

While it would not appreciably speed up the lunar landing timetable, he said,

NASA could achieve the goal of placing a man on the moon within the decade.

The Houston Post, January 18, 1963.

January 18

Two aerodynamic strakes were added to the CM to eliminate the

danger of a hypersonic apex-forward trim point on reentry. [During a

high-altitude launch escape system (LES) abort, the crew would undergo excessive

g forces if the CM were to trim apex forward. During a low-altitude abort, there

was the potential problem of the apex cover not clearing the CM. See November

1962. The strakes, located in the yaw plane, had a maximum span of one foot and

resulted in significant weight penalties. The size of the strakes had to be

increased later because of changes in the CM which moved the center of gravity

forward and because of the additional ablative material needed to combat the

increased heating of the strakes during reentry. Removal of the strakes would

cause a major redesign to permit the apex cover to be jettisoned in the low

angle-of-attack (apex forward) region. In the summer of 1963, however, MSC and

North American representatives agreed that the strakes should be removed and an

apex-mounted flap be added. The flap could be jettisoned with the LES tower

during normal missions and retained with the CM during a LES abort.

North American then suggested a "tower flap dual mode" approach. This concept

incorporated fixed surfaces at the upper end of the LES tower which would be

exposed to the air stream after jettison of the expended rocket casing, For

aborts below 9,140 meters (30,000 feet), the jettison motor would pull away the

expended motor casing, the LES tower, and apex cover. The contractor carried out

extensive wind tunnel tests of this configuration and reported to MSC during

October that a 0.5941-square-meter (920-square-inch) planer flap located in the

upper bay of the LES, coupled with a more favorable CM center of gravity, would

be required to solve the reentry problem.

An independent investigation of deployable aerodynamic surfaces, or canards,

at the forward end of the LES rocket motor was also being conducted. These

canards would act as lifting surfaces to destabilize the LES and cause it to

reorient the spacecraft to a heatshield-forward position. (See November 12,

1963, February 7 and 25, 1964.)

"Apollo Monthly Progress Report," SID 62-300-9, p. 6; ibid., SID

62-300-10, p. 5; ibid., SID 62-300-11, April 1, 1963, p. 7;

ibid., SID 62-300-12, p. 8; ibid., SID 62-300-15,

August 1, 1963, p. 5; ibid., SID 62- 300-16, September 1, 1963, p.

8; ibid., SID 62-300-17, October 1, 1963, p. 5; ibid.,

SID 62-300-18, November 1, 1963, p. 3; ibid., SID 62-300-19,

December 1, 1963, p. 5; ibid., SID 62-300-20, January 1, 1964, p.

5; ibid., SID 62-300-21, February 1, 1964, p. 3;

ibid., SID 62 300-23, April 1, 1964, p. 3; "ASPO Weekly Activity

Report, September 19-25, 1963," p. 3; "ASPO Weekly Activity Report, September

26-October 2, 1963,"p. 2; "ASPO Status Report For Period Ending October 16,

1963"; "ASPO Status Report For Period October 16-November 12, 1963"; "ASPO

Status Report For Period December 18-January 14, 1964"; "ASPO Status Report For

Week Ending December 4, 1963"; "ASPO Status Report For Week Ending December 17,

1963"; "ASPO Status Report For Week Ending January 7, 1964"; "Monthly ASPO

Status Report For Period January 16-February 12, 1964"; "Apollo Quarterly Status

Report No. 3," p. 32; "Apollo Quarterly Status Report No. 4 for Period Ending

June 30, 1963," p. 28; "Apollo Quarterly Status Report No. 5 for Period Ending

September 30, 1963," p. 40; "Apollo Quarterly Status Report No. 6 for Period

Ending December 31, 1963,"p. 37; MSC, "Weekly Activity Report for the Office of

the Director, Manned Space Flight, June 30July 6, 1963," p. 4; "Minutes of

NASA-NAA Technical Management Meeting, February 25, 1964"; Oakley,

Historical Summary, S&ID Apollo Program, p. 12.

January 18

NASA's Flight Research Center (FRC) announced the award of a

$3.61 million contract to Bell Aerosystems Company of Bell Aerospace Corporation

for the design and construction of two manned lunar landing research vehicles.

The vehicles would be able to take off and land under their own power, reach an

altitude of about 1,220 meters (4,000 feet), hover, and fly horizontally. A fan

turbojet engine would supply a constant upward push of five-sixths the weight of

the vehicle to simulate the one-sixth gravity of the lunar surface. Tests would

be conducted at FRC.

Astronautics and Aeronautics, 1963 (NASA SP-4004), p. 17;

Daily Press, Newport News, Va., January 13, 1963; Wall Street

Journal, January 22, 1963; Aviation Daily, January 24, 1963,

p. 161.

January 23

The Hamilton Standard space suit contract was amended to

include supplying space suit communications and telemetry equipment. (See

November 27, 1962.)

Hamilton Standard, "Monthly Progress Report for the Period of January 1

through 31, 1963, for Apollo Space Suit Assembly," PR-4-1-63, p. 1.

January 24

The first evaluation of crew mobility in the International

Latex Corporation (ILC) pressure suit was conducted at North American to

identify interface problems. Three test subjects performed simulated flight

tasks inside a CM mockup. CM spatial restrictions on mobility were shown.

Problems involving suit sizes, crew couch dimensions, and restraint harness

attachment, adjustment, and release were appraised. Numerous items that

conflicted with Apollo systems were noted and passed along to ILC for correction

in the continuing suit development program. (See March 26-28.)

"Project Apollo Spacecraft, Test Program Weekly Activities Report (Period, 21

January 1963 through 27 January 1963)," p. 6.

January 26

MSC announced new assignments for the seven original

astronauts: L. Gordon Cooper, Jr., and Alan B. Shepard, Jr., would be

responsible for the remaining pilot phases of Project Mercury; Virgil I. Grissom

would specialize in Project Gemini; John H. Glenn, Jr., would concentrate on

Project Apollo; M. Scott Carpenter would cover lunar excursion training; and

Walter M. Schirra, Jr., would be responsible for Gemini and Apollo operations

and training. As Coordinator for Astronaut Activities, Donald K. Slayton would

maintain overall supervision of astronaut duties.

Specialty areas for the second generation were: trainers and simulators, Neil

A. Armstrong; boosters, Frank Borman; cockpit layout and systems integration,

Charles Conrad, Jr.; recovery system, James A. Lovell, Jr.; guidance and

navigation, James A. McDivitt; electrical, sequential, and mission planning,

Elliot M. See, Jr.; communications, instrumentation, and range integration,

Thomas P. Stafford; flight control systems, Edward H. White II; and

environmental control systems, personal equipment, and survival equipment, John

W. Young.

MSC Fact Sheet No. 113, "Specialized Assignments for MSC Astronauts and

Flight Crew Personnel," January 26, 1963; The Washington Post,

January 27, 1963.

January 28

NASA announced the selection of the Philco Corporation as

prime contractor for the Mission Control Center (MCC) at MSC. To be operational

in mid-1964, MCC would link the spacecraft with ground controllers at MSC

through the worldwide tracking network.

NASA News Release 63-14, "Philco to Develop Manned Flight Mission Control

Center at Houston," January 28, 1963; Wall Street Journal, January

29, 1963.

January 28

Following a technical conference on the LEM electrical power

system (EPS), Grumman began a study to define the EPS configuration. Included

was an analysis of EPS requirements and of weight and reliability for fuel cells

and batteries. Total energy required for the LEM mission, including the

translunar phase, was estimated at 61.3 kilowatt-hours. Upon completion of this

and a similar study by MSC, Grumman decided upon a three-cell arrangement with

an auxiliary battery. Capacity would be determined when the EPS load analysis

was completed. (See March 7.)

"Apollo Quarterly Status Report No. 3," pp. 27-28.

Ground was broken for the MSC Operations and Checkout Building at

Merritt Island January 28, 1963. Participants were, left to right, Walter C.

Williams, Director of Flight Operations, MSC; G. Merritt Preston, Director of

Pre-Flight Operations Division, MSC; Kurt H. Debus, Director, Launch Operations

Center; D. Brainerd Holmes, Director, NASA Office of Manned Space Flight;

Wernher von Braun, Marshall Space Flight Center; Col. H. R. Parfitt, District

Engineer, U.S. Army; and Col. E. Richardson, U.S. Air Force.

January 30

Grumman and NASA announced the selection of four companies as

major LEM subcontractors:

- Rocketdyne for the descent engine (see February 13)

- Bell Aerosystems Company for the ascent engine (see February 25)

- The Marquardt Corporation for the reaction control system (see March 11)

- Hamilton Standard for the environmental control system see (March

4).

MSC News Release 63-14, January 30, 1963; Aviation

Daily, January 30, 1963, p. 210; Wall Street Journal,

January 31, 1963.

During the Month

MSC awarded a contract to Chance Vought Corporation for

a study of guidance system techniques for the LEM in an abort during lunar

landing.

NASA News Release 63-41, "January Contracts," March 4, 1963.

NASA authorized North American to extend

until June 10 the CM heatshield development program. This gave the company time

to evaluate and recommend one of the three ablative materials still under

consideration. The materials were subjected to tests of thermal performance,

physical and mechanical properties, and structural compatibility with the

existing heatshield substructure. North American sought also to determine the

manufacturing feasibility of placing the materials in a Fiberglas honeycomb

matrix bonded to a steel substructure. (See November 1962.)

Letter, H. P. Yschek, MSC, to NAA, Space and Information Systems Div.,

"Contract Change Authorization No. Thirteen, Revision 2," March 11, 1963.

February 1

Walter C. Williams, MSC's Associate Director, defined the

Center's criteria on the location of earth landing sites for Gemini and Apollo

spacecraft: site selection as well as mode of landing (i.e., land versus water)

for each mission should be considered separately. Constraints on trajectory,

landing accuracy, and landing systems must be considered, as well as lead time

needed to construct landing area facilities. Both Gemini and Apollo flight

planning had to include water as well as land landing modes. (See December

1962.) Although the Apollo earth landing system was designed to withstand the

shock of coming down on varying terrains, some experience was necessary to

verify this capability. Because of the complexity of the Apollo mission and

because the earth landing system did not provide a means of avoiding obstacles,

landing accuracy was even more significant for Apollo than for Gemini. With so

many variables involved, Williams recommended that specific landing locations

for future missions not be immediately designated. (See March 5 and February 25,

1964.)

Memorandum, Walter C. Williams, MSC, to NASA Headquarters, Attn: OMSF,

"Designation of Landing Sires for Projects Gemini and Apollo," February 1, 1963.

February 6

Aerojet-General Corporation, Sacramento, Calif., began

full-scale firings of a service propulsion engine with a redesigned injector

baffle.

MSC, "Consolidated Activity Report for the Office of the Director, Manned

Space Flight, January 27-February 23, 1963," p. 56.

February 7

NASA announced a simplified terminology for the Saturn

booster series: Saturn C-1 became "Saturn I," Saturn C-1B became "Saturn IB,"

and Saturn C-5 became "Saturn V."

MSC Fact Sheet No. 136, "NASA Simplifies Names of Saturn Launch Vehicles,"

February 7, 1963.

February 8

MSC issued a definitive contract for $15,029,420 to the

Raytheon Company, Space and Information Systems Division, to design and develop

the CM onboard digital computer. The contract was in support of the MIT

Instrumentation Laboratory, which was developing the Apollo guidance and

navigation systems. Announcement of the contract was made on February 11.

MSC, "Consolidated Activity Report for the Office of the Director, Manned

Space Flight, January 27-February 23, 1963," p, 29; MSC News Release 63-18,

February 11, 1963; Missiles and Rockets, 12 (February 18, 1963), p.

42.

February 11

The first inertial reference integrating gyro produced by AC

Spark Plug was accepted by NASA and delivered to the MIT Instrumentation

Laboratory. (See November 1962.)

MSC, "Consolidated Activity Report for the Office of the Director, Manned

Space Flight, January 27-February 23, 1963," p. 57.

February 12

NASA selected the Marion Power Shovel Company to design and

build the crawler-transport, a device to haul the Apollo space vehicle (Saturn

V, complete with spacecraft and associated launch equipment) from the Vertical

Assembly Building to the Merritt Island, Fla., launch pad, a distance of about

5.6 kilometers (3.5 miles). The crawler would be 39.6 meters (130 feet) long, 35

meters (115 feet) wide, and 6 meters (20 feet) high, and would weight 2.5

million kilograms (5.5 million pounds). NASA planned to buy two crawlers at a

cost of $4 to 5 million each. Formal negotiations began on February 20 and the

contract was signed on March 29.

Saturn Illustrated Chronology (MHR-3, August 10, 1964), p. 73;

NASA News Release 63-27, "Marion to Build NASA Crawler," February 12, 1963.

February 13

In a reorganization of ASPO, MSC announced the appointment

of two deputy managers. Robert O. Piland, deputy for the LEM, and James L.

Decker, deputy for the CSM, would supervise cost, schedule, technical design,

and production. J. Thomas Markley was named Special Assistant to the Apollo

Manager, Charles W. Frick. Also appointed to newly created positions were

Caldwell C. Johnson, Manager, Spacecraft Systems Office, CSM; Owen E. Maynard,

Acting Manager, Spacecraft Systems Office, LEM; and David W. Gilbert, Manager,

Spacecraft Systems Office, Guidance and Navigation.

MSC News Release 63-27, February 13, 1963.

February 13

Grumman began discussions with Rocketdyne on the development

of a throttleable LEM descent engine. Engine specifications (helium injected,

10:1 thrust variation) had been laid down by MSC. (See May 1.)

MSC, "Consolidated Activity Report for the Office of the Director, Manned

Space Flight, January 27-February 23, 1963," p. 57; "Apollo Quarterly Status

Report No. 3," p. 25.

February 15

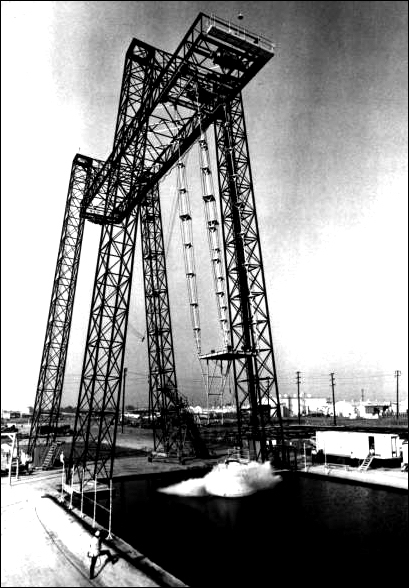

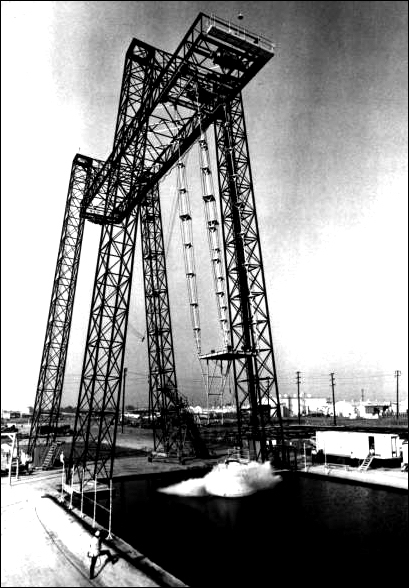

A boilerplate spacecraft is dropped in the impact test facility at

NAA's Downey, Calif., plant. The tower was 43.6 meters (143 feet) high, the

pendulum pivot was 38.1 meters (125 feet), and maximum impact velocity was 12.2

meters (40 feet) per second vertical and 15.2 meters (50 feet) per second

horizontal. (NAA photo)

The North American Apollo impact test facility at Downey, Calif., was

completed. This facility consisted mainly of a large pool with overhead

framework and mechanisms for hydrodynamic drop tests of the CM. Testing at the

facility began with the drop of boilerplate 3 on March 11.

Oakley, Historical Summary, S&ID Apollo Program, p. 8;

"Apollo Monthly Progress Report," SID 62-300-11, pp. 10, 21.

February 18

NASA issued a definitive contract for $6,322,643 to General

Dynamics Convair for the Little Joe II test vehicle. (See May 11, 1962, Vol. I.)

A number of changes defined by contract change proposals were incorporated into

the final document:

- Four instead of five vehicles to be manufactured and delivered

- Launching from White Sands Missile Range (WSMR), N.M., instead of Cape

Canaveral

- Additional support equipment, better definition of vehicle design, and

responsibility for launch support.

Little Joe II Test Launch

Vehicle, NASA Project Apollo: Final Report, Vol. I, pp. 1-2, 1-4; MSC,

"Consolidated Activity Report for the Office of the Director, Manned Space

Flight, January 27-February 23, 1963," p. 28.

February 18

North American selected Bell Aerosystems Company to provide

propellant tanks for the CSM reaction control system. These tanks were to be the

"positive expulsion" type (i.e., fuel and oxidizer would be contained inside

flexible bladder; pressure against one side of the device would force the

propellant through the RCS lines).

"Apollo Monthly Progress Report," SID 62-300-10, p. 3; Aviation

Daily, February 18, 1963, p. 312.

February 19

North American shipped CM boilerplate 19 to Northrop Ventura

for use as a parachute test vehicle.

MSC, "Consolidated Activity Report for the Office of the Director, Manned

Space Flight, January 27-February 23, 1963," p. 55.

February 20

At a meeting of the MSC-MSFC Flight Mechanics Panel, it was

agreed that Marshall would investigate "engine-out" capability (i.e., the

vehicle's performance should one of its engines fail) for use in abort studies

or alternative missions. Not all Saturn I, IB, and V missions included this

engine-out capability. Also, the panel decided that the launch escape system

would be jettisoned ten seconds after S-IV ignition on Saturn I launch vehicles.

(See March 28.)

MSC, "Consolidated Activity Report for the Office of the Director, Manned

Space Flight, January 27-February 23, 1963," p. 58.

February 20

In a reorganization of OMSF, Director D. Brainerd Holmes

appointed Joseph F. Shea as Deputy Director for Systems and George M. Low as

Deputy Director for Programs. All major OMSF directorates had previously

reported directly to Holmes. In the new organizational structure, Director of

Systems Studies William A. Lee, Director of Systems Engineering John A.

Gautraud, and Director of Integration and Checkout James E. Sloan would report

to Shea. Director of Launch Vehicles Milton W. Rosen, Director of Space Medicine

Charles H. Roadman, and the Director of Spacecraft and Flight Missions (then

vacant) would report to Low. William E. Lilly, Director of Administration, would

provide administrative support in both major areas.

NASA News Release 63-32, "Holmes Names Two Deputies," February 20, 1963;

The Washington Post, February 21, 1963.

February 21

MSC issued a Request for Proposals (due by March 13) for a

radiation altimeter system. Greater accuracy than that provided by available

radar would be needed during the descent to the lunar surface, especially in the

last moments before touchdown. Preliminary MSC studies had indicated the general

feasibility of an altimeter system using a source-detector-electronics package.

After final selection and visual observation of the landing site, radioactive

material would be released at an altitude of about 30 meters 100 feet and

allowed to fall to the surface. The detector would operate in conjunction with

electronic circuitry to compute the spacecraft's altitude. Studies were also

under way at MSC on the possibility of using laser beams for range

determination.

Memorandum, George W. Brandon, MSC, to Asst. Dir. for Information and Control

Systems, "Request for Proposal, Low Level Radiation Altimeter System," November

13, 1962; Aviation Daily, February 21, 1963, p. 335.

February 24-March 23

The MSC Lunar Surface Experiments Panel held its

first meeting. This group was formed to study and evaluate lunar surface

experiments and the adaptability of Surveyor and other unmanned probes for use

with manned missions.

MSC, "Consolidated Monthly Activity Report for the Office of the Director,

Manned Space Flight, February 24-March 23, 1963," p. 44.

February 25

Grumman began initial talks with the Bell Aerosystems

Company on development of the LEM ascent engine. Complete specifications were

expected by March 2.

MSC, "Consolidated Activity Report for the Office of the Director, Manned

Space Flight, January 27-February 23, 1963," p. 28.

February 25

MSC ordered North American to provide batteries, wholly

independent of the main electrical system in the CM, to fire all pyrotechnics

aboard the spacecraft.

Letter, H. P. Yschek, MSC, to NAA, Space and Information Systems Div.,

"Contract Change Authorization No. Twenty-Eight," February 25, 1963.

February 25

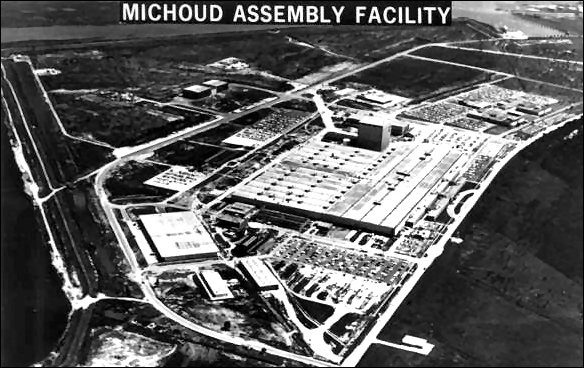

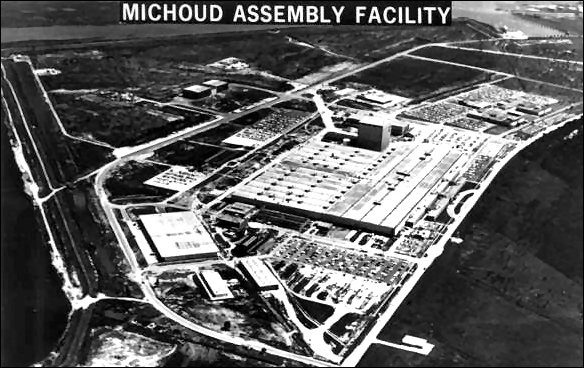

Aerial view of the Michoud Operations Plant, New Orleans, La

NASA announced the signing of a formal contract with The Boeing Company for

the S-IC (first stage) of the Saturn V launch vehicle, the largest rocket unit

under development in the United States. The $418,820,967 agreement called for

the development and manufacture of one ground test and ten flight articles.

Preliminary development of the S-IC, which was powered by five F-1 engines, had

been in progress since December 1961 under a $50 million interim contract.

Booster fabrication would take place primarily at the Michoud Operations Plant,

New Orleans, La., but some advance testing would be done at MSFC and the

Mississippi Test Operations facility.

NASA News Release 63-37, "NASA Contracts with Boeing for Saturn V Booster,"

February 25, 1963; Aviation Daily, February 27, 1963, p. 361.

February 26

Two aerospace technologists at MSC, James A. Ferrando and

Edgar C. Lineberry, Jr., analyzed orbital constraints on the CSM imposed by the

abort capability of the LEM during the descent and hover phases of a lunar

mission. Their study concerned the feasibility of rendezvous should an emergency

demand an immediate return to the CSM.

Ferrando and Lineberry found that, once abort factors are considered, there

exist "very few" orbits that are acceptable from which to begin the descent.

They reported that the most advantageous orbit for the CSM would be a

147-kilometer (80-nautical-mile) circular one.

Memorandum, James A. Ferrando and Edgar C. Lineberry, Jr., to Chief, Flight

Operations Div., "The Influence of LEM Abort Capability Upon the Selection of

the Command Module Lunar Orbit," February 26, 1963.

February 26

NASA selected Ford, Bacon, and Davis, Inc., to design MSC's

flight acceleration facility, including a centrifuge capable of spinning a

simulated CM and its crew at gravity forces equal to those experienced in space

flight.

Space Business Daily, February 26, 1963, p. 243; Aviation

Daily, February 26, 1963, p. 358.

February 27

Aviation Daily reported an announcement by Frank Canning,

Assistant LEM Project Manager at Grumman, that a Request for Proposals would be

issued in about two weeks for the development of an alternate descent propulsion

system. Because the descent stage presented what he called the LEM's "biggest

development problem," Canning said that the parallel program was essential.

Aviation Daily, February 27, 1963, p. 362.

February 27

The Apollo Mission Planning Panel held its organizational

meeting at MSC. The panel's function was to develop the lunar landing mission

design, coordinate trajectory analyses for all Saturn missions, and develop

contingency plans for all manned Apollo missions.

Membership on the panel included representatives from MSC, MSFC, NASA

Headquarters, North American, Grumman, and MIT, with other NASA Centers being

called on when necessary. By outlining the most accurate mission plan possible,

the panel would ensure that the spacecraft could satisfy Apollo's anticipated

mission objectives. Most of the panel's influence on spacecraft design would

relate to the LEM, which was at an earlier stage of development than the CSM.

The panel was not given responsibility for preparing operational plans to be

used on actual Apollo missions, however.

MSC, "Minutes of Meeting on Apollo Mission Planning Panel Organization

Meeting, February 27, 1963," March 7, 1963.

February 27

Elgin National Watch Company received a subcontract from

North American for the design and development of central timing equipment for

the Apollo spacecraft. [This equipment provided time-correlation of all

spacecraft time-sensitive events. Originally, Greenwich Mean Time was to be used

to record all events, but this was later changed. (See August 30-September 5,

1963.)]

Chicago Tribune, February 27, 1963; Wall Street

Journal, February 28, 1963.

During the Month

Grumman began fabrication of a one-tenth scale model of

the LEM for stage separation tests. In launching from the lunar surface, the

LEM's ascent engine fires just after pyrotechnic severance of all connections

between the two stages, a maneuver aptly called "fire in the hole."

Also, Grumman advised that, from the standpoint of landing stability, a

five-legged LEM was unsatisfactory. Under investigation were a number of landing

gear configurations, including retractable legs. (See April 17 and May 20-22.)

Grumman Aircraft Engineering Corporation [hereafter cited as GAEC], "Monthly

Progress Report No. 1, LPR-10-1, March 10, 1963," pp. 5, 6, 8.

During the Month

NASA amended the GE contract, authorizing the company's

Apollo Support Department to proceed with the PACE program. (See March 25,

1964.) [PACE (prelaunch automatic checkout equipment) would be used for

spacecraft checkout. It would be computer-directed and operated by remote

control.]

GE, "Support Program Monthly Progress Report, February 1963," NASw-410-MR-2.

[NOTE: Use of the acronym "PACE" was subsequently dropped at the insistence of a

company claiming prior rights to the name.]

Grumman began initial discussions with

Hamilton Standard on the development of the LEM environmental control system.

MSC, "Consolidated Activity Report for the Office of the Director, Manned

Space Flight, January 27-February 23, 1963," p. 57; "Consolidated Monthly

Activity Report for the Office of the Director, Manned Space Flight, February

24-March 23, 1963," p. 8.

March 4

As a parallel to the existing Northrop Ventura contract, and

upon authorization by NASA, North American awarded a contract for a solid

parachute program to the Pioneer Parachute Company. [A solid parachute is one

with solid (unbroken) gores; the sole opening in the canopy is a vent at the

top. Ringsail parachutes (used on the Northrop Ventura recovery system) have

slotted gores. In effect, each panel formed on the gores becomes a "sail."] (See

June 28.)

"Apollo Quarterly Status Report No. 3," p. 18; letter, H. P. Yschek, MSC, to

NAA, Space and Information Systems Div., "Contract Change Authorization No.

Twenty-Seven," February 25, 1963.

March 4

MSC "acquired" under a loan agreement an amphibious landing

craft from the Army. Equipment to retrieve Apollo boilerplate spacecraft and

other objects used in air drops and flotation tests was installed. The vessel,

later named the Retriever, arrived at its Seabrook, Tex., docking

facility late in June.

MSC News Release 63-38, "MSC Acquires Test Vehicle," March 4, 1963; MSC,

Space News Roundup, June 26, 1963, p. 1.

March 5

MSC awarded a $67,000 contract to The Perkin-Elmer Corporation

to develop a carbon dioxide measurement system, a device to measure the partial

carbon dioxide pressure within the spacecraft's cabin. Two prototype units were

to be delivered to MSC for evaluation. About seven months later, a $249,000

definitive contract for fabrication and testing of the sensor was signed. (See

May 6.)

MSC, "Consolidated Monthly Activity Report for the Office of the Director,

Manned Space Flight, February 24-March 23, 1963," p. 30; "Consolidated Activity

Report for the Office of the Director, Manned Space Flight, September 22-October

19, 1963," p. 47.

March 5

NASA announced an American agreement with Australia, signed on

February 26, that permitted the space agency to build and operate several new

tracking stations "down under." A key link in the Jet Propulsion Laboratory's

network of Deep Space Instrumentation Facilities would be constructed in

Tidbinbilla Valley, 18 kilometers (11 miles) southwest of Canberra. Equipment at

this site included a 26-meter (85-foot) parabolic dish antenna and electronic

equipment for transmitting, receiving, and processing radio signals from

spacecraft. Tracking stations would be built also at Carnarvon and Darwin.

NASA News Release 63-47, "NASA to Establish Deep Space Tracking Facility in

Australia," March 5, 1963; Aviation Daily, March 8, 1963, p. 52.

March 5

The Mission Analysis Branch (MAB) of MSC's Flight Operations

Division cited the principal disadvantages of the land recovery mode for Apollo

missions. (See February 1.) Of primary concern was the possibility of landing in

an unplanned area and the concomitant dangers involved. For water recovery, the

main disadvantages were the establishment of suitable landing areas in the

southern hemisphere and the apex-down flotation problem. MAB believed no

insurmountable obstacles existed for either approach. (See February 25, 1964.)

Memorandum, John Bryant, MSC, to Chief, FOD, "Operational Considerations in

the Selection of Primary Land or Sea Return Areas for Apollo," March 5, 1963.

March 6

North American completed construction of Apollo boilerplate (BP)

9, consisting of launch escape tower and CSM. It was delivered to MSC on March

18, where dynamic testing on the vehicle began two days later. On April 8, BP-9

was sent to MSFC for compatibility tests with the Saturn I launch vehicle.

MSC, "Consolidated Monthly Activity Report for the Office of the Director,

Manned Space Flight, February 24-March 23, 1963," p. 50; Oakley,

Historical Summary, S&ID Apollo Program, p. 8; Birmingham

Post-Herald, April 5, 1963; The Huntsville Times, April 9,

1963; The Birmingham News, April 9, 1963.

March 6

The first Block I Apollo pulsed integrating pendulum

accelerometer, produced by the Sperry Gyroscope Company, was delivered to the

MIT Instrumentation Laboratory. [Three accelerometers were part of the guidance

and navigation system. Their function was to sense changes in spacecraft

velocity.]

MSC, "Consolidated Monthly Activity Report for the Office of the Director,

Manned Space Flight, February 24-March 23, 1963," p. 53.

March 7

Grumman representatives presented their technical study report

on power sources for the LEM. (See January 28.) They recommended three fuel

cells in the descent stage (one cell to meet emergency requirements), two sets

of fluid tanks, and two batteries for peak power loads. For industrial

competition to develop the power sources, Grumman suggested Pratt and Whitney

Aircraft and GE for the fuel cells, and Eagle-Picher, Electrical Storage

Battery, Yardney, Gulton, and Delco-Remy for the batteries.

"Activity Report, RASPO/GAEC, 3/3/63-3/9/63" (undated), pp. 1-2.

March 8

North American moved CM boilerplate (BP) 6 from the

manufacturing facilities to the Apollo Test Preparation Interim Area at Downey,

Calif. During the next several weeks, BP-6 was fitted with a pad adapter, an

inert launch escape system, and a nose cone, interstage structure, and motor

skirt. (See July 1-2 and November 7.)

MSC, "Postlaunch Memorandum Report for Apollo Pad Abort I," November 13,

1963, pp. A1-1 through A1-5.

March 10

Grumman presented its first monthly progress report on the LEM.

In accordance with NASA's list of high-priority items, principal engineering

work was concentrated on spacecraft and subsystem configuration studies, mission

plans and test program investigations, common usage equipment surveys, and

preparation for implementing subcontractor efforts.

"Monthly Progress Report No. 1," LPR-10-1, p. 4.

March 11

Grumman completed its first "fire-in-the-hole" model test. (See

February 1963.) Even though preliminary data agreed with predicted values, they

nonetheless planned to have a support contractor, the Martin Company, verify the

findings.

"Activity Report, RASPO/GAEC, 3/10/63-3/16/63" (undated), p. 2.

March 11

NASA announced signing of the contract with Grumman for

development of the LEM. (See November 19, 1962.) Company officials had signed

the document on January 21 and, following legal reviews, NASA Headquarters had

formally approved the agreement on March 7. Under the fixed-fee contract (NAS

9-1100) ($362.5 million for costs and $25.4 million in fees) Grumman was

authorized to design, fabricate, and deliver nine ground test and 11 flight

vehicles. The contractor would also provide mission support for Apollo flights.

MSC outlined a developmental approach, incorporated into the contract as

"Exhibit B, Technical Approach," that became the "framework within which the

initial design and operational modes" of the LEM were developed.

NASA-MSC, "Lunar Excursion Module, Project Apollo, Exhibit B, Technical

Approach, Contract NAS 9-1100," December 20, 1962, p. 1; MSF Management Council

Meeting, January 29, 1963, Agenda Item 3, "MSC Status Report," pp. 23, 26; MSF

Management Council Minutes, January 29, 1963, p. 3; MSC, "Consolidated Monthly

Activity Report for the Office of the Director, Manned Space Flight, February

24-March 23, 1963,"p. 29; "Apollo Quarterly Status Report No. 3," p. 1; NASA

News Release 63-51, "Contract Signed to Develop Lunar Excursion Module," March

11, 1963.

March 11

Grumman began early contract talks with the Marquardt

Corporation for development of the LEM reaction control system.

MSC, "Consolidated Activity Report for the Office of the Director, Manned

Space Flight, January 27-February 23, 1963," p. 57; "Consolidated Monthly

Activity Report for the Office of the Director, Manned Space Flight, February

24-March 23, 1963," p. 7.

March 13

The first stage of the Saturn SA-5 launch vehicle was static

fired at MSFC for 144.44 seconds in the first long-duration test for a Block II

S-1. The cluster of eight H-1 engines produced 680 thousand kilograms (1.5

million pounds) of thrust. An analysis disclosed anomalies in the propulsion

system. In a final qualification test two weeks later, when the engines were

fired for 143.47 seconds, the propulsion problems had been corrected.

MSFC Historical Office, History of the George C. Marshall Space Flight Center

from January 1 through June 30, 1963 (MHM-7), Vol. I, pp. 21-22; The Huntsville

Times, March 14,1963.

March 14

A bidders' conference was held at Grumman for a LEM

mechanically throttled descent engine to be developed concurrently with

Rocketdyne's helium injection descent engine. (See February 27.) Corporations

represented were Space Technology Laboratories; United Technology Center, a

division of United Aircraft Corporation; Reaction Motors Division, Thiokol

Chemical Corporation; and Aerojet-General Corporation. Technical and cost

proposals were due at Grumman on April 8.

"Activity Report, RASPO/GAEC, 3/10/63-3/16/63" (undated), p. 1.

March 14

Homer E. Newell, Director of NASA's Office of Space Sciences,

summarized results of studies by Langley Research Center and Space Technology

Laboratories on an unmanned lunar orbiter spacecraft. These studies had been

prompted by questions of the reliability and photographic capabilities of such

spacecraft. Both studies indicated that, on a five-shot program, the probability

was 0.93 for one and 0.81 for two successful missions; they also confirmed that

the spacecraft would be capable of photographing a landed Surveyor to assist in

Apollo site verification.

Memorandum, Newell, NASA, to Dir., OMSF, "Questions on the unmanned lunar

orbiter," March 14, 1963, with four enclosures; Bruce K, Byers, "Lunar Orbiter:

a Preliminary History" (HHN-71), August 1969, pp. 21-22.

March 20

John A. Hornbeck, president of Bellcomm, testified before the

House Committee on Science and Astronautics' Subcommittee on Manned Space Flight

concerning the nature and scope of Bellcomm's support for NASA's Apollo program.

In answer to the question as to how Bellcomm would decide "which area would be

the most feasible" for a lunar landing, Hornbeck replied, ". . . the safety of

the landing - that will be the paramount thing." He said that his company was

studying a number of likely areas, but would "not recommend a specific site at

the moment." Further, "Preliminary studies . . . suggest that the

characteristics of a 'good' site for early exploration might be (1) on a lunar

sea, (2) 10 miles [16 kilometers] from a continent, and (3) 10 miles [16

kilometers] from a postmarial crater." This type of site, Hornbeck said, would

permit the most scientific activity practicable, and would enable NASA's

planners to design future missions for even greater scientific returns.

U.S. Congress, House, Subcommittee on Manned Space Flight of the Committee on

Science and Astronautics, 1964 NASA Authorization, Hearings on H.R.

5466 (Superseded by H.R. 7500), [No. 3] Part 2(a), 88th Cong., 1st Sess. (1963),

p. 378.

March 21

MSC awarded the Philco Corporation a definitive contract (worth

almost $33.8 million) to provide flight information and flight control display

equipment (with the exception of the realtime computer complex) for the Mission

Control Center at MSC. NASA Headquarters approved the contract at the end of the

month.

MSC, "Consolidated Monthly Activity Report for the Office of the Director,

Manned Space Flight, February 24-March 23, 1963," p. 29; "Apollo Quarterly

Status Report No. 3," p. 49; Space Business Daily, April 4, 1963,

p. 432.

March 25

General Dynamics Convair completed structural assembly of the

first launcher for the Little Joe II test program. During the next few weeks,

electrical equipment installation, vehicle mating, and checkout were completed.

The launcher was then disassembled and delivered to WSMR on April 25, 1963.

Little Joe II Test Launch Vehicle, NASA Project Apollo: Final

Report, Vol. I, pp. 1-4 and 1-6.

March 25-31

North American analyzed lighting conditions in the CM and

found that glossy or light-colored garments and pressure suits produced

unsatisfactory reflections on glass surfaces. A series of tests were planned to

define the allowable limits of reflection on windows and display panel faces to

preclude interference with crew performance.

"Project Apollo Spacecraft Test Program, Weekly Activity Report (Period 25

March 1963 through 31 March 1963)," p. 5.

March 26

Hamilton Standard Division awarded a contract to ITT/Kellogg

for the design and manufacture of a prototype extravehicular suit telemetry and

communications system to be used with the portable life support system. (See

November 27, 1962.)

Memorandum, Michael B. Luse, MSC, to Crew Systems Division, Attn: M. I.

Radnofsky, "Extra-Vehicular Suit Telemetry and Communication System," March 11,

1964.

March 26

MSC announced the beginning of CM environmental control system

tests at the AiResearch Manufacturing Company simulating prelaunch, ascent,

orbital, and reentry pressure effects. Earlier in the month, analysis had

indicated that the CM interior temperature could be maintained between 294 K (70

degrees F) and 300 K (80 degrees F) during all flight operations, although

prelaunch temperatures might rise to a maximum of 302 K (84 degrees F).

"Apollo Monthly Progress Report," SID 62-300-11, p. 12; MSC News Release

63-61, March 26, 1963.

March 26-28

A meeting was held at North American to define CM-space suit

interface problem areas. (See January 24.) Demonstrations of pressurized

International Latex suits revealed poor crew mobility and task performance

inside the CM, caused in part by the crew's unavoidably interfering with one

another.

Other items received considerable attention: A six-foot umbilical hose would

be adequate for the astronaut in the CM. The location of spacecraft water,

oxygen, and electrical fittings was judged satisfactory, as were the new couch

assist handholds. The astronaut's ability to operate the environmental control

system (ECS) oxygen flow control valve while couched and pressurized was

questionable. Therefore, it was decided that the ECS valve would remain open and

that the astronaut would use the suit control valve to regulate the flow. It was

also found that the hand controller must be moved about nine inches forward.

Memorandum, J. F. Saunders, Jr., RASPO/NAA, to L. McMillion, MSC, "Data

Transmittal," April 5, 1963, with enclosures: Agenda and Minutes of Meeting,

"Command Module-Space Suit Interface Meeting No. 4, NAA, Downey - 26, 27, 28

March 1963."

March 27

The Apollo Mission Planning Panel (see February 27) set forth

two firm requirements for the lunar landing mission. First, both LEM crewmen

must be able to function on the lunar surface simultaneously. MSC contractors

were directed to embody this requirement in the design and development of the

Apollo spacecraft systems. Second, the panel established duration limits for

lunar operations. These limits, based upon the 48-hour LEM operation

requirement, were 24 hours on the lunar surface and 24 hours in flight on one

extreme, and 45 surface hours and 3 flight hours on the other. Grumman was

directed to design the LEM to perform throughout this range of mission profiles.

MSC, "Abstract of Meeting on Apollo Mission Planning Meeting No. 1, March 27,

1963," March 29, 1963; memorandum, Robert V. Battey, MSC, to Action Committee,

"Errata to Abstract of Mission Planning Panel Meeting No. 1," April 1, 1963.

March 28

NASA launched Saturn SA-4 from Cape Canaveral. The S-I Saturn

stage reached an altitude of 129 kilometers (80 statute miles) and a peak

velocity of 5,906 kilometers (3,660 miles) per hour. This was the last of four

successful tests for the first stage of the Saturn I vehicle. After 100 seconds

of flight, No. 5 of the booster's eight engines was cut off by a preset timer.

That engine's propellants were rerouted to the remaining seven, which continued

to burn. This experiment confirmed the "engine-out" capability that MSFC

engineers had designed into the Saturn I. (See February 20.)

Saturn Illustrated Chronology, pp. 76-77; History of

Marshall . . . January 1-June 30, 1963, Vol. I, pp. 16-18.

During a visit to NAA during March 1963, Astronauts M. Scott Carpenter,

John H. Glenn, Jr., and Walter M. Schirra, Jr., took time out to "try the

spacecraft of for size." The spacecraft mockup was one of the items inspected as

they toured the NAA spacecraft facilities at Downey, Calif.

During the Month

North American selected two subcontractors to build

tankage for the SM: Allison Division of General Motors Corporation to fabricate

the fuel and oxidizer tanks; and Airite Products, Inc., those for helium

storage.

"Apollo Monthly Progress Report," SID 62-300-11, p. 3.

During the Month

RCA completed a study on ablative versus regenerative

cooling for the thrust chamber of the LEM ascent engine. Because of low cooling

margins available with regenerative cooling, Grumman selected the ablative

method, which permitted the use of either ablation or radiation cooling for the

nozzle extension. (See September 19-October 16.)

"Apollo Quarterly Status Report No. 3," p. 26; GAEC, "Monthly Progress Report

No. 2," LPR-10-2, April 10, 1963, p. 12.

During the Month

Grumman met with representatives of North American,

Collins Radio Company, and Motorola, Inc., to discuss common usage and

preliminary design specifications for the LEM communications system. These

discussions led to a simpler design for the S-band receiver and to modifications

to the S-band transmitter (required because of North American's design

approach).

"Monthly Progress Report No. 2," LPR-10-2, p. 15.

During the Month

MSC sent MIT and Grumman radar configuration

requirements for the LEM. The descent equipment would be a three-beam doppler

radar with a two-position antenna. Operating independently of the primary

guidance and navigation system, it would determine altitude, rate of descent,

and horizontal velocity from 7,000 meters (20,000 feet) above the lunar surface.

The LEM rendezvous radar, a gimbaled antenna with a two-axis freedom of

movement, and the rendezvous transponder mounted on the antenna would provide

tracking data, thus aiding the LEM to intercept the orbiting CM. The SM would be

equipped with an identical rendezvous radar and transponder.

"Apollo Quarterly Status Report No. 3," p. 23.

During the Quarter

MSC reported that preliminary plans for Apollo

scientific instrumentation had been prepared with the cooperation of NASA

Headquarters, Jet Propulsion Laboratory, and the Goddard Space Flight Center.

The first experiments would not be selected until about December 1963, allowing

scientists time to prepare proposals. Prime consideration would be given to

experiments that promised the maximum return for the least weight and

complexity, and to those that were man-oriented and compatible with spacecraft

restraints. Among those already suggested were seismic devices (active and

passive), and instruments to measure the surface bearing strength, magnetic

field, radiation spectrum, soil density, and gravitational field. MSC planned to

procure most of this equipment through the scientific community and through

other NASA and government organizations.

Ibid., p. 30.

During the Quarter

To provide a more physiologically acceptable load

factor orientation during reentry and abort, MSC was considering revised angles

for the crew couch in the CM. To reduce the couch's complexity, North American

had proposed adjustments which included removable calf pads and a movable head

pad. (See April 3.)

Ibid., p. 6.

During the Quarter

MSC reported that stowage of crew equipment, some of

which would be used in both the CM and the LEM, had been worked out. Two

portable life support systems and three pressure suits and thermal garments were

to be stowed in the CM. Smaller equipment and consumables would be distributed

between modules according to mission phase requirements.

Ibid., p. 22.