Part 3 (A)

Developing Software Ground Rules

April 29, 1964 through June 1964

1964

April

1964

May

1964

June

April 29

ASPO defined weight and volume allocations for scientific

equipment. Exact location of this equipment could not be specified, but each

module had to have the following capacities:

- CM and LEM ascent stage: 36 kilograms (80 pounds); 0.06 cubic meter (2

cubic feet)

- LEM descent stage: 95 kilograms (210 pounds); 0.27 cubic meter (9 cubic

feet), minimum; 0.45 cubic meter (15 cubic feet), design objective.

Any

additional space gained by jettisoning expendable equipment could also be used

for storage. (See June 8.)

Requirements for thermal protection for the scientific equipment were not yet

defined, nor was the packaging concept. Electrical outlets on the LEM,

furnishing power to the equipment, would of course have to be within the reach

of an astronaut while he was standing on the moon's surface outside the

spacecraft.

Letter, W. F. Rector III, MSC, to GAEC, Attn: R. S. Mullaney, "Contract NAS

9-1100, Scientific Equipment," April 29, 1964.

April 29

MSC established new LEM abort guidance ground rules, which

defined the operation and reliability requirements of the stabilization and

control system's abort guidance section. Grumman was to continue studies on the

abort pitch programmer and on the capability of the LEM to perform rendezvous.

Letter, W. F. Rector III, MSC, to GAEC, Attn: R. S. Mullaney, "Contract NAS

9-1100, Abort Guidance Section of the Stabilization and Control Subsystem,"

April 29, 1964.

April 30

Communications links between CM, LEM, and earth stations.

MSC authorized major revisions in the CM communications system to provide

better voice and data relay between the CM, the LEM, and ground stations.

Letter, H. P. Yschek, MSC, to NAA, Space and Information Systems Div.,

"Contract Change Authorization No. 201," April 30, 1964.

April 30

Following a series of 15 acceptance firings at Rocketdyne's

Santa Susana test facility (conducted during March and April), the first

hot-firing production J-2 engine was delivered to Douglas Aircraft Company

(DAC). The engine then began "battleship" testing (i.e., fitted to a heavyweight

stage of the vehicle built especially for static testing) at DAC's Sacramento

test site.

Akens, et al., History of Marshall . . . January 1 through

June 30, 1964, Vol. I, pp. 148, 224.

During the Month

Grumman awarded Bell Aerosystems Company the contract

for the LEM ascent stage reaction control system propellant tanks. The contract

was worth about $3.5 million.

Missiles and Rockets, 14 (April 27, 1964), p. 23.

During the Month

Grumman recommended using a self-stabilized trim gimbal

system in the descent stage of the LEM, which would save about 34 kilograms (75

pounds) of reaction control system propellant.

"Monthly Progress Report No. 15," LPR-10-31, p. 24.

MSC Structures and Mechanics Division began

vibration tests on SM boilerplate (BP) 22 to determine resonant frequencies,

mode shapes, and structural damping characteristics. The results would be used

in evaluation of data from the BP-22 flight test of the launch escape system at

WSMR, scheduled for 1965.

MSC, "Consolidated Activity Report for the Office of the Associate

Administrator, Manned Space Flight, April 19-May 16, 1964," p. 56; MSC News

Release 64-86, May 1, 1964.

May 1

ASPO Manager Joseph F. Shea reported to the Senior Staff that NASA

was not imposing any requirement for the crew to get out of the CM quickly

should some problem arise with the launch vehicle while on the pad. Given such

an occurrence with the crewmen perched almost 122 meters (400 feet) high - and

atop a fueled Saturn V - it was believed more rational to make a standard abort

(using the launch escape system) or to hold the countdown until the vehicle

could be made safe.

MSC, "Minutes of Senior Staff Meeting, May 1, 1964," p. 3.

May 1

MSC Instrumentation and Electronic Systems Division personnel

visited Jet Propulsion Laboratory to review the Surveyor landing radar test

program and to investigate the use of either a reflector or a transponder on the

Surveyor to help in the selection of landing sites for the LEM. At that time,

the possibility did not appear promising because reflector usage seemed

impractical and because power requirements were far above what was available.

Additional study on the matter was planned.

MSC, "ASPO Management Report for Period April 23-30, 1964"; "ASPO Management

Report for Period April 3-May 7, 1964."

May 1

Grumman completed negotiations with RCA for the attitude and

translation control assembly (ATCA) for the LEM. The ATCA imposed thrust demands

on the vehicle's stabilization and control system based upon information from

the guidance equipment.

MSC, "Consolidated Activity Report for the Office of the Associate

Administrator, Manned Space Flight, April 19-May 16, 1964," p. 45.

May 4

The Apollo Mission Planning Task Force presented its Phase I

progress report to ASPO. (See November 29, 1963, and January 16, 1964.) ASPO, in

assigning this task, had defined its principal objectives: the determination of

mission-related, functional requirements for spacecraft subsystems; the

examination of current subsystem capabilities to meet these requirements; the

evaluation of the capability of the spacecraft to fly missions which met the

program objectives; the determination of flexibilities available within

established control weights; and the provision of mission plans which would be

the basis for other analyses and reporting.

The task force further refined program objectives:

- to land two astronauts and scientific equipment on the near-earth-side of

the moon and return them safely to earth; and

- to perform experiments within the restrictions of 113 kilograms (250

pounds) and 0.3 cubic meter (10 cubic feet) of scientific payload, which would

be landed on the lunar surface, and 36 kilograms (80 pounds) and 0.06 cubic

meter (two cubic feet), which would be returned to earth.

Mission

related spacecraft design rules were studied. Seventeen rules for spacecraft

operations and seven for contingencies were selected. Although trajectory ground

rules were considered more operational than design in nature, the group included

16 as necessary to define the performance capabilities of the spacecraft design.

A reference trajectory, provided by MSC, assumed a launch date of May 8, 1968,

and a 41,000- kilogram (90,000-pound spacecraft injected into a 66.4-hour

translunar-coast/free-return trajectory.

GAEC, "Apollo Mission Planning Task Force, Phase I Progress Report,"

LED-540-7, Vols. I, II, III, May 4, 1964.

May 4-11

MSC ordered Grumman to halt all work on a radiatively cooled

nozzle for the LEM's ascent engine. (See January; also see September 19-October

16, 1963.) The Center took this action largely to avoid schedule slippage

(because the work was drawing valuable people away from the "mainstream" effort,

an ablative nozzle). Also involved in the cancellation were such factors as high

risk and cost; the lack of previous experience with this type; and the minor

saving in weight at best.

MSC, "ASPO Weekly Management Report, May 7-14, 1964."

May 5

MSC Operations Planning Division (OPD) reviewed power usage aboard

the LEM if the fuel cell assembly (FCA) failed. OPD concluded that Grumman's

requirements were too stringent (i.e., turning off all equipment not needed for

lunar landing should one FCA fail and turning off everything not needed for crew

safety following an abort should two FCA's fail). OPD planned to review all

subsystems to determine their duty cycles after an FCA-dictated abort.

MSC,"ASPO Management Report for Period April 30-May 7, 1964."

May 6

NASA selected RCA for negotiation of a contract for C-band radar

equipment to be used on tracking ships by NASA and the Department of Defense,

under the U.S. Navy Instrumentation Ships Project Office, during lunar missions.

NASA News Release 64-107, "NASA Selects RCA Radar for Tracking Ships," May 6,

1964.

May 7

ASPO notified Grumman that a number of components must remain as

common- use items, because they were used in conjunction with government

furnished equipment that was interchangeable between the two spacecraft: oxygen

and water disconnects on the portable life support system and quick-disconnects

for the suit umbilicals. ASPO added suit umbilicals and carbon dioxide sensors

to the common-use list.

ASPO decided that the Gemini pressure suit would be used in Apollo Block I

earth orbital flights and, on May 19, notified North American accordingly. This

decision grew out of continuing mobility problems with Apollo prototype suit,

especially restrictive inside the spacecraft. (See April 28-30.)

MSC, "Minutes of Senior Staff Meeting, May 8, 1964," p. 4; MSC, "ASPO Weekly

Management Report, May 14-21, 1964."

May 7-14

At MSC's request, Grumman studied the use of the LEM

stabilization and control system in aligning that vehicle's inertial measurement

unit before spacecraft separation. The company found that the maneuver would

consume 5.33 kilograms (11.74 pounds) of fuel from the vehicle's stabilization

and control system (SCS), compared with 2.83 kilograms (6.24 pounds) for the

same alignment with a free LEM. Grumman advised that the best procedure would be

to use the CSM to position the LEM telescope field of view. The LEM could then

begin the necessary drift for sighting, using less than 0.23 kilogram (0.5

pound) of SCS fuel.

Also, Grumman studied the feasibility of an overhead window at the command

pilot's station in the LEM. The contractor was pursuing the question of the

optimum window size and location and the type of reticle required. (See April 24

and May 22.)

MSC, "ASPO Weekly Management Report, May 7-14, 1964."

May 7-14

North American completed the environmental requirements for the

CM television camera. The camera must be able to function under conditions of

100 percent humidity, including unhooking and reconnecting the cable. Also,

because of the humidity requirement and the "outgassing" properties of

commercial lenses (that is, the gases which they could possibly give off inside

the spacecraft's cabin), North American decided that a special zoom lens would

have to be developed, which would cost around $110,000.

Ibid.

May 8

NASA and The Boeing Company signed a contract for five Lunar

Orbiter spacecraft. Under the incentive provisions, Boeing could receive up to

$5.3 million more than the basic $80 million cost if all Lunar Orbiter missions

were successful. (See December 20, 1963.)

NASA News Release 64-109, "NASA Signs Contract with Boeing for Lunar

Orbiter," May 8, 1964.

May 8

ASPO Manager Joseph F. Shea told the Center's Senior Staff that it

was imperative to decide whether to use the gas-cooled space suit or the

liquid-cooled undergarment. (See February 1.) Studies had shown that the current

gas-cooled suit would not meet the heat load requirements and improvement would

be difficult. Shea felt that parallel developments should not be carried out. A

more conservative approach might be to adopt the liquid-cooled garment, which

could readily handle the heat load, although it entailed some increase in weight

and cost, if it could be developed and qualified within the next four years. On

May 22, Robert O. Piland, Shea's Deputy, reported to the Staff that

liquid-cooled undergarments had been selected for the Block II spacecraft. (See

July.)

In line with selection of the liquid-cooled undergarment, Hamilton Standard

was directed to stop work on the gas-cooled and begin work on a watercooled

portable life support system (PLSS). On June 3, Grumman was officially notified

that the PLSS was being redesigned to include a liquid transport loop for

removal of heat from inside the space suit. This would be done by the

liquid-cooled garment and incorporation of flexible tubing through which a

coolant would be circulated. Current PLSS interfaces would be used to the

greatest practical extent. It was expected that the new undergarments would

first be used in manned flight about mid-1967.

MSC, "Minutes of Senior Staff Meeting, May 8, 1964," p. 4; "Minutes of Senior

Staff Meeting, May 22, 1964," p. 4; MSC, "ASPO Weekly Management Report, May

14-21, 1964"; letter, W. F. Rector III, MSC, to GAEC, Attn: R. S. Mullaney,

"Contract NAS 9-1100, Portable life support system changes," June 3, 1964.

May 11-18

After a 444-second firing, Rocketdyne's first LEM descent

engine prototype thrust chamber developed a hot gas leak at the injector flange.

Studies were under way by the contractor to determine the cause of the leak.

MSC, "Consolidated Activity Report for the Office of the Associate

Administrator, Manned Space Flight, May 17-June 20, 1964," p. 24; MSC, "ASPO

Weekly Management Report, May 14-21, 1964."

May 12

Verne C. Fryklund, Jr., Chief of the Lunar and Planetary Branch

in NASA's Office of Space Science and Applications, reported that the Lunar

Orbiter program was being coordinated with Apollo's requirements for moon maps.

This agreement was reached through a series of meetings of Fryklund with William

B. Taylor, of OMSF's Advanced Manned Missions Program Directorate; and Lee R.

Scherer, Lunar Orbiter Program Manager. Fryklund set forth general requirements

for maps for the Apollo program. Because most Lunar Orbiter data were intended

for Apollo's use, Fryklund said, these requirements must be borne in mind when

Lunar Orbiter's information was analyzed and distributed. MSC was interested

primarily in the equatorial area of the moon (10 degrees above and below the

equator), and established rather stringent demands for accuracy around selected

landmarks. These requirements were dictated by Apollo's need for selenodetic and

topographic information, essential for lunar navigation and landing site

selection and for scientific activities by the astronauts on the lunar surface.

Although each mission might ultimately require special maps, Fryklund advised,

major requirements could be met by a common series of charts and photomosaics.

Memorandum, Fryklund, NASA, to Distr., "The Lunar Orbiter Program and the

lunar mapping requirements of Project Apollo," May 12, 1964.

May 13

Apollo's first flight test using the Little Joe II launch

vehicle, Mission A-001, using CSM boilerplate (BP) 12, was launched from WSMR.

The test was conducted to determine aerodynamic characteristics of the launch

escape system (LES) and its capability to pull the spacecraft away from the

launch vehicle during an abort at transonic speeds and high dynamic pressure.

Thrust termination subjected the spacecraft to an environment more severe than

expected, above the qualification test level of many of the CM's components.

he planned sequence of events for the BP-12 sub-orbital flight is shown

above.

Except for a parachute failure, spacecraft and LES functioned flawlessly. All

but one test objective was met: because of excessive spacecraft oscillation at

the time the main parachutes were deployed, one riser was dragged across the

spacecraft structure and severed. The shroud lines of the now-freed parachute

burned a gore in one of the two remaining parachutes. Although the damaged gore

failed, these two main parachutes deployed normally. BP-12 landed 3,530 meters

(11,600 feet) downrange about five minutes and 50 seconds after liftoff. At

impact, its rate of descent was 7.9 meters (26 feet) per second, 0.06 meters

(two feet) per second faster than planned but still within human tolerances.

"Postlaunch Report for Apollo Mission A-001 (BP-12)," pp. 1-1, 2-1, 3-1, 6-1.

May 14-21

MSC decided to provide equipment in the LEM for recording the

astronauts' voices, and was studying ways to achieve a capability for time

correlation with a minimum increase in power and weight.

MSC, "ASPO Weekly Management Report, May 14-21, 1964."

May 18-25

The first test of a fully ablative thrust chamber for the LEM

descent engine was held at Space Technology Laboratories. The chamber, with a

wall thickness of 22.4 millimeters (0.88 inch), was fired for 488 seconds.

Although some charring occurred, there was no streaking or gouging. Data showed

good performance at low thrust.

MSC, "ASPO Weekly Management Report, May 21-28, 1964"; MSC, "Weekly Activity

Report for the Office of the Associate Administrator, Manned Space Flight, May

24-30, 1964."

May 21

General Electric (GE) issued a report on postlanding tilt angles

for the LEM (the result of a study ordered by ASPO). The Apollo Systems

Specification, put out by OMSF, called for the LEM's ability to lift off from

the moon from an angle of 30 degrees; MSC's LEM Technical Approach stated that

"the Lunar Touchdown System [i.e., the landing gear] will be required to land

the LEM in a near vertical position satisfactory for lunar launch and normal

egress." GE's study was an attempt to reconcile this difference. There was some

concern that, for a variety of reasons, a 30-degree tilt might be undesirable:

the spacecraft could tip over; once stage separation occurred, the vehicle's

ascent portion could shift slightly; and the crew's visibility and mobility -

including their ability to get in and out of the craft - might be impaired.

Added to this were possible constraints imposed by the performance of many of

the LEM's operational systems (e.g., communications, ascent propulsion,

stabilization and control). In sum, GE reported that it had found no constraints

that negated the 30-degree figure, and recommended that MSC's Technical Approach

be revised to correspond with OMSF's specification.

General Electric Company, Apollo Support Department, "Study of the

Postlanding Tilt Angle of the LEM," TIR 545-S64-03-006, May 21, 1964,

passim, but especially pp. 1-4, 32-34; MSC, "ASPO Weekly Management

Report, May 21-28, 1964"; interview, telephone, Richard H. Kohrs, Houston, March

9, 1970.

May 21

NASA completed negotiations with General Dynamics/Convair (GD/C)

for two additional Little Joe II test vehicles and associated ground equipment.

(See February 18, 1963.) The amendment (worth $1,352,050) increased the

contract's total estimated cost and fee to $12,478,205, and brought to eight the

total number of Little Joes (excluding the qualification vehicle) that NASA

bought from GD/C.

MSC,"Consolidated Activity Report for the Office of the Associate

Administrator, Manned Space Flight, May 17-June 20, 1964,"p. 42; Little

Joe II Test Launch Vehicle, NASA Project Apollo: Final Report, Vol. I,

pp. 1-7, 4-4.

May 21-28

North American completed zero-g egress tests, using the

proposed small configuration CM side entry hatch with a crewman wearing a

pressurized Gemini space suit and an operational portable life support system.

Weightless tests were also conducted on the crew couch zero-g restraint harness.

The subjects had considerable difficulty attaching the harness; additional

development and testing were necessary.

NAA, "Apollo Monthly Progress Report," SID 62-300-26, July 1, 1964, p. 7;

MSC, "ASPO Weekly Management Report, May 28-June 4, 1964."

May 22

ASPO directed Grumman to provide an overhead window in the LEM to

permit the pilot to dock at the upper docking hatch. The forward access hatch

was retained for lunar surface ingress and egress and on-the- pad access

capabilities. The contractor would remove the forward docking interface and

tunnel.

MSC, "ASPO Weekly Management Report, May 21-28, 1964"; MSC, "Minutes of

Senior Staff Meeting, May 22, 1964," p. 4.

May 22

MSC received results of RCA and Ryan Aeronautical Company studies

on modifying either the LEM landing or rendezvous radar to achieve the high

accuracies needed to circularize the LEM's lunar orbit. The contractors

concluded that, as currently designed, radar performance would be marginal.

Attempts to obtain this degree of accuracy could cause schedules to slip,

because of the lack of knowledge of lunar reflectivity. As a means of reducing

the effects of surface variations, RCA and Ryan recommended lessening the

spectrum of the radar. (See February 27-March 4 and March 16.)

MSC, "ASPO Weekly Management Report, May 21-28, 1964"; MSC, "Consolidated

Activity Report for the Office of the Associate Administrator, Manned Space

Flight, May !7-June 20, 1964," p. 58.

May 22

MSC informed Grumman of two major revisions to the ground rules

for crew transfer between the two spacecraft:

- Definite tasks were replaced with a general requirement that a

"pressurized crew,' should be able to prepare the docked spacecraft for

translunar operations.

- The requirement for a crewman to pressurize his space suit and, with the

aid of a second crewman, move through the transfer tunnel without damage to

the suit was changed: the crew must be able to transfer through the tunnel in

a pressurized suit as a degraded mode of operation.

Transfer in an

unpressurized suit continued to be the primary and extravehicular transfer the

emergency mode. Crew transfer tests at North American indicated that no

significant hardware changes were necessary to implement these revisions.

Letter, W. F. Rector III, MSC, to GAEC, Attn: R. S. Mullaney, "Revision of

the Apollo-Docking Interface and Ground Rules," May 22, 1964.

May 26

At Hamilton Standard, MSC representatives reviewed status of the

Apollo space suit (A3H-024). Tests showed that a suited astronaut could not put

on the thermal coverall while wearing a portable life support system.

MSC, "ASPO Weekly Management Report, May 28-June 4, 1964."

May 26

ASPO notified Grumman that the carbon dioxide sensor was a crew

safety item. Since failure of this component could cause loss of the crew, it

must be designed to meet crew safety reliability. NASA's contract with The

Perkin-Elmer Corporation, manufacturer of the; sensor, had been amended to

include testing required for crew safety items.

Letter, W. F. Rector III, MSC, to GAEC, Attn: R. S. Mullaney, "Contract NAS

9-1100, carbon dioxide (CO2) sensor requirement," May 26, 1964.

May 26

ASPO directed North American to provide a station in the CM where

the astronauts could put on and remove the portable life support systems.

MSC, "ASPO Weekly Management Report, May 21-28, 1964."

May 27

Meetings at Grumman (on May 21-22) had disclosed that the

contractor had changed from an all-welded LEM cabin to one that was partially

riveted. Although this change had not been coordinated with MSC, the Center

nonetheless agreed to it, provided the structural integrity of a cabin thus

fabricated could be demonstrated under all load, temperature, and vacuum

conditions. MSC recommended that representatives from Grumman visit MSFC to

review welding and sealant techniques developed for Saturn launch vehicles.

MSC, "ASPO Weekly Management Report, May 28-June 4, 1964."

May 28

Apollo Mission A-101, the first flight of an Apollo spacecraft

with a Saturn launch vehicle, was launched from Cape Kennedy. The purpose of the

flight was to demonstrate the compatibility of the spacecraft with the launch

vehicle for earth orbital flights. A-101 also was the first Apollo flight test

conducted at Cape Kennedy, and consisted of CSM boilerplate (BP) 13 and the

Saturn SA-6 vehicle.

Launch azimuth was 105 degrees. S-I's first stage number eight engine shut

down prematurely at T+1 16.9 seconds, delaying S-I cutoff and separation, which

occurred at T+148.8 seconds (2.7 seconds late). The S-IV second stage ignited at

T+150.9 seconds, and the LES was jettisoned 10.3 seconds later and was propelled

safely from the flight path. S-IV cutoff took place at T+624.5 seconds (l.26

seconds earlier than predicted). Orbit insertion was completed at T+629.5

seconds, with a 31.78 degree equatorial plane. The payload weight at orbit

insertion was 7,622 kilograms (17,023 pounds). Deviations from planned flight

path angle and velocity were minus 0.05 degrees and plus 3.6 meters (11 feet)

per second, respectively. Orbital parameters were 182 and 227 kilometers (98.4

and 122.5 nautical miles); the orbital period was 88.62 minutes.

Although there were a few cases of excessive delay in transmission, data

coverage and availability were, in general, quite good. Electromagnetic

interference was minor and did not degrade or invalidate the data. The

instrumentation and communications systems performed satisfactorily; battery

performances exceeded expectations. LES separation caused no detectable

disturbance of the flight vehicle. The sequencer system, explosive bolts, and

tower jettison all functioned properly. Aerodynamic, thermodynamic, acoustic,

and vibration data contained no surprises. As expected, stresses on the LES were

considerably less than those imposed during abort; loads on other spacecraft

structures all were within design limits.

BP-13 and the spent S-IV stage circled the earth 54 times before reentering

the atmosphere east of Canton Island in the Pacific Ocean on June 1. No

spacecraft recovery was planned.

NAA, "Project Apollo Flight-Test Report, Boilerplate 13," SID 63-1416-3,

August 1964, pp. 2-1, 2-2; "Postlaunch Report for Apollo Mission A-101 (BP-13),"

pp. 2-1, 3-2 through 3-5, 4-l through 4-3, 7-1.

May 28

MSC issued a cost-plus-fixed-fee contract to Bissett-Berman

Corporation of Santa Monica, Calif., for studies of Apollo mission planning,

guidance and navigation system analysis, and related tasks. The contract was

valued at $915,357.

MSC, "Consolidated Activity Report for the Office of the Associate

Administrator, Manned Space Flight, May 17-June 20, 1964," p. 42.

May 28

MSC instructed North American to continue the Apollo food studies

(being done under subcontract by the Stanford Research Center) on diet

selection, nutritional value, packaging design and materials, and rehydration.

North American was asked to furnish a final report documenting the project and

to provide MSC Crew Systems Division with one set (i.e., food supply for three

crewmen for a two-week Apollo mission) for evaluation of both the food itself

and of packaging concepts. The contractor also was asked to report its findings

on studies of snacks for the crewmen.

Letter, H. P. Yschek, MSC, to NAA, Space and Information Systems Div.,

"Contract Change Authorization No. 174, Revision 1," May 28, 1964,

May 28-June 4

MSC reported that Grumman was studying how much restraint

the LEM crew needed during lunar landing, and was conducting manned drop tests

to help define requirements. The program was divided into two phases, one on

vertical and the other on off-axis landing. In the first part, already

completed, the subject had needed no restraints. The second phase, however, was

much more severe, and it was believed that restraint would probably be

essential.

MSC, "ASPO Weekly Management Report, May 28-June 4, 1964"; "Quarterly Status

Report No. 8," p. 35.

During the Month

At the CSM mockup review at North American on April

28-30, MSC officials were concerned about the complexity of the couch restraint

system. Because of the decision that primary landing would be on water (see

February 28), the system was reviewed. Based upon load analyses, supplemented by

manned tests at Holloman Air Force Base, a simpler system (principally a

combination lap belt and shoulder harness) was found acceptable.

MSC, "ASPO Weekly Management Report, May 14-21, 1964"; "Quarterly Status

Report No. 8," pp. 12-13.

MSC notified Grumman that primary LEM ingress

and egress was through the forward hatch. To aid the LEM crew in getting down to

the lunar surface and in climbing back into their vehicle, the Center said, a

narrow platform must be provided from the hatch to the landing gear knuckle

(which became the "front porch"), and a handrail and ladder down the strut to

the foot pad.

MSC, "ASPO Weekly Management Report, June 4-11, 1964."

June 1-5

Technicians of MSC's Landing and Recovery Division began

initial testing with a prototype flotation collar (similar to those used with

both Mercury and Gemini spacecraft). Boilerplate 25 served as the test vehicle.

MSC, Space News Roundup, June 24, 1964, p. 3.

June 2

NASA signed a production contract worth $1.82 million with Sperry

Gyroscope for accelerometers for the CSM's navigation and guidance system. (See

Volume I, May 8, 1962.) [Sperry Gyroscope had been chosen during the first half

of 1962 to develop these devices, and a developmental contract had been signed

on June 1 of that year.]

NASA Contract NAS 9-2847, June 2, 1964.

June 3

ASPO confirmed for Grumman that no conclusive requirement for a

LEM emergency detection system (EDS) had been established. The LEM should be

designed to preclude any potential failure which could cause a time- critical

emergency. Malfunctions which were not time-critical would be monitored by the

caution and warning system while the LEM was manned. Equipment which operated

during unmanned periods should be designed to present minimum hazard and to shut

down or discharge in a safe condition in cases of malfunction.

ASPO therefore directed Grumman to take no further action on an EDS for the

LEM; to analyze possible failures continuously to ensure that safety

requirements were met; and to advise ASPO if, at any time, those analyses

indicated increased criticality which might warrant reconsideration of an EDS.

Letter, W. F. Rector III, MSC, to GAEC, Attn: R. S. Mullaney, "Contract NAS

9-1100, Lunar Excursion Module Recommendation Concerning LEM Emergency

Detection," June 3, 1964.

June 4

After studying several configurations for the probe and drogue

docking concept, North American recommended one particular design: three radial

attenuators attached to three pitch arms, a probe head, a sliding center probe,

a stored gas retracting mechanism, and three probe-to-tunnel mounting arms. This

configuration would be about 15 percent lighter than the single, center probe,

attenuator configuration.

MSC, "ASPO Weekly Management Report, June 4-11, 1964."

June 4-11

North American assessed the ultraviolet energy emitted from

the shock layer surrounding a spacecraft during reentry. The contractor sought

to determine how much that energy added to the radiative heat load imposed on

the vehicle, and what effect it would have on the amount of ablative material on

the CM. North American's first estimates placed the figure at about 20 percent

for lunar return velocities (a figure that thermodynamics experts at MSC called

"very conservative"), which would cause about a 4.5-kilogram (10- pound)

increase in ablator weight. Because ultraviolet emissions were insignificant at

orbital speeds, MSC's Structures and Mechanics Division recommended that their

effect be considered only for the design of the Block II CM's heatshield.

Ibid.

June 8

ASPO redefined the allowances for scientific equipment in the LEM

ascent stage. Major changes were the increase of storage space from 0.06 to 0.09

cubic meter (two to three cubic feet) and of weight from 36 to 45 kilograms (80

to 100 pounds). (See April 29.)

Letter, W. F. Rector III, MSC, to GAEC, Attn: R. S. Mullaney, "Contract NAS

9-1100, Scientific Equipment," June 8, 1964.

June 8

A test of the landing impact and stability test program was

conducted at North American's drop facility. CM boilerplate 2 was tested with

the centerline perpendicular to the water at a vertical speed of 10.4 meters (34

feet) per second. For the first time, a self-contained instrumentation package

was installed in the dummy in the center couch. The other two dummies were not

instrumented. Onboard cameras documented the general motions and responses

during impact. No motion of the dummies in couches or restraint harnesses was

observed, indicating that support and restraint were excellent. The simulated

heatshield ruptured, as expected.

NAA, "Apollo Monthly Progress Report," SID 62-300-27, August 1, 1964, pp.

5-7, 17; MSC, "ASPO Weekly Management Report, June 4-11, 1964"; interview,

telephone, Glenn W. Briggs, RASPO/NAA, January 12, 1970.

June 9

In response to a Grumman request, ASPO provided information on

LEM crew provision requirements. Caloric requirements, management, packaging,

and reconstitution of food supplies were spelled out in detail.

Letter, W. F. Rector III, MSC, to GAEC, Attn: R. S. Mullaney, "Contract NAS

9-1100, LEM crew provisions," June 9, 1964.

June 9

MSC announced the letting of a $67,261 contract to Geonautics,

Inc., for a study of LEM navigation using lunar landmarks for reference.

Geonautics would evaluate crew techniques and procedures for choosing safe

landing sites, navigational devices and displays in the LEM, navigational data

on the spacecraft's position and trajectory, errors to be expected using various

methods of navigation, and the value of available lunar maps.

MSC News Release 64-109, June 9, 1964.

June 9

Micro Systems, a subsidiary of Electro-Optical Systems, received

two North American contracts valued at $1.85 million to provide temperature and

pressure transducer instrumentation for the CM.

Space Business Daily, June 9, 1964, p. 212.

June 9

Intending to rely on redundant and backup systems to ensure the

spacecraft's reliability, MSC ordered North American to discontinue all effort

on the inflight test and maintenance concept for the CM, including spare parts.

Letter, H. P. Yschek, MSC, to NAA, Space and Information Systems Div.,

"Contract Change Authorization No. 213," June 9, 1964.

June 9

MSC clarified design criteria for the launch escape vehicle

(LEV). During initial portions of the first-stage flight, when range safety

considerations precluded thrust termination (estimated to be 40 seconds), the

LEV must be capable of aborting safely. Also, the LEV structure must be designed

to withstand loads arising from tumbling or oscillating.

MSC, "ASPO Weekly Management Report, June 4-11, 1964."

Early June

MSC geologist Ted H. Foss described a simulated lunar surface

(modeled after the Kepler crater in the Oceanus Procellarum) to be constructed

at MSC. It would be used for geological training of astronauts and for studying

their mobility in space suits. The 100-meter (328-foot)-diameter area would be

covered mainly with slag. Plans for several craters about 15 meters (50 feet) in

diameter and 4.6 meters (15 feet) deep were later altered to include a large

crater 19.5 meters (64 feet) in diameter and 4.9 meters (16 feet) deep and a

smaller crater 12.2 meters (40 feet) in diameter and 3 meters (10 feet) deep.

There would be a major ridge, 102.4 meters (336 feet) long and 3.7 meters (12

feet) high, and about 75 small craters less than 1.2 meters (4 feet) in

diameter. [The mock lunar surface was completed in December.]

MSC, Space News Roundup, June 10, 1964, p. 7; MSC News Release

64-194, December 21, 1964.

Early June

NASA notified Grumman, MIT, and North American that RCA would

furnish the CSM rendezvous radar to be used with the radar equipment on the LEM.

A purchase order for the additional units was issued.

"Apollo Quarterly Status Report No. 8," p. 46.

June 11

MSC directed North American to make a number of changes to the

Block II CSM configuration, some of which were mandatory for Block I vehicles as

well. This action followed reviews of the contractor's CSM Block II Technical

Report at Houston and at NASA Headquarters (by Apollo Program Director Samuel C.

Phillips and OMSF chief George E. Mueller) during May. (See April 16.)

Basically, these changes (including a number to the spacecraft's subsystems)

were imposed by the requirements of a lunar mission. Most pertained to the CM

per se: provisions for docking (including visual aids) and redesign of the

transfer tunnel; capability for extravehicular transfer; and adding portable

life support systems and scientific equipment. Micrometeoroid protection had to

be added to the SM. (See September 30.)

Memorandum, Owen E. Maynard, MSC, to Addressees, "CSM Block II changes

transmitted to NAA for implementation," June 19, 1964, with enclosure: letter,

H. P. Yschek, MSC, to NAA, Space and Information Systems Div., Attn: E. E. Sack,

"Block II changes," June 11, 1964, with enclosures.

June 11-18

North American canceled its contract with Avien, Inc., for

the CSM S- band high-gain antenna system. (See June 21-27, 1963.) Between July

16 and August 15, North American awarded 90-day study contracts to Hughes

Aircraft Company and GE to determine the best approach for developing these

antennas for Block II spacecraft. The studies were scheduled for completion in

October.

MSC, "Apollo/E and D Technical Management Meeting No. 5," June 3, 1964, p. 1;

MSC, "ASPO Weekly Management Report, June 11-18, 1964"; NAA, "Apollo Monthly

Progress Report," SID 62-300-28, September 1, 1964, p. 8.

June 12

MSC and Space Technology Laboratories (STL) completed

negotiations (begun May 12) on a $4.6 million cost-plus-fixed-fee contract for a

Mission Trajectory Control Program, a continuing project begun in September 1963

to analyze Gemini missions. STL would develop computer programs for flight

control trajectories, orbital maneuvers, and analyses of guidance systems, range

safety, and mission error. NASA Headquarters approved the contract on August 18

and announced the contract award on August 20.

MSC, "Consolidated Activity Report for the Office of the Associate

Administrator, Manned Space Flight, July 19-August 22, 1964," p. 42;

"Consolidated Activity Report for the Office of the Associate Administrator,

Manned Space Flight, May 17-June 20, 1964," p. 43; NASA News Release 64-206,

"STL to Compute Gemini, Apollo Missions Simulations," August 20, 1964.

June 12

MSC approved Grumman's subcontract (valued at $9,411,144) with

Pratt and Whitney Aircraft for the LEM fuel cell assembly.

On this same day, the Center awarded a letter contract with a total estimated

cost and fee of $3.315 million to AC Spark Plug for the LEM guidance and

navigation and coupling display unit. (See October 18, 1963.)

MSC, "Consolidated Activity Report for the Office of the Associate

Administrator, Manned Space Flight, June 21-July 18, 1964," p. 37.

June 15

Space Business Daily reported that MSC was developing a

packaging system for bringing back uncontaminated lunar specimens for study.

First, the Center would explore methods for collecting, storing, and shipping

geological, chemical, and biological specimens in their original conditions to

earth laboratories. MSC then would award a contract for production of the

system.

Space Business Daily, June 15, 1964, p. 239.

June 16

ASPO notified Grumman that the use of reclaimed high explosives

was undesirable, since this might reduce the reliability and quality of

pyrotechnic systems. To trace any lot of reclaimed material to its point of

origin was virtually impossible, nor could adulterants such as TNT, which might

have been added for original military use, be easily removed. MSC therefore

directed North American to use only virgin, newly manufactured high explosives

in Apollo pyrotechnic devices and systems.

Letter, W. F. Rector III, MSC, to GAEC, Attn: R. S. Mullaney, "Contract NAS

9-1100, High explosives in the Apollo Spacecraft," June 16, 1964.

June 16

A realignment of CSM guidance and navigation subsystems

functions was mandatory for Block II spacecraft. MSC therefore directed North

American and MIT to conduct a program definition study of these systems. MSC

outlined Block II responsibilities, systems changes (both required and desired),

and implementation requirements and assigned responsibilities in these areas to

the appropriate contractors.

Letter, H. P. Yschek, MSC, to NAA, Space and Information Systems Div.,

"Contract Change Authorization No. 216," June 16, 1964, with enclosure: "Notes

for CSM Block II, Definition Discussions," June 4, 1964.

June 17

NASA selected Collins Radio Company for an estimated $20 million

fixed-price-plus-incentive-fee contract to fabricate, install, integrate, and

test unified S-band tracking, data acquisition, and communications equipment for

Manned Space Flight Network stations. Chosen from 14 competing firms, Collins

would provide NASA with nine systems, each with a 9-meter (30-foot)-diameter

parabolic antenna. Six of these would be integrated into facilities being

prepared for Gemini flights and three would be installed at new Apollo stations.

About 30 partial systems would also be integrated into existing ground stations

for tracking Apollo flights.

NASA News Release 64-116, "NASA Negotiating Apollo Communications Systems

Contracts," May 14, 1964; NASA News Release 64-146, "NASA Selects Collins Radio

to Provide Apollo Tracking Systems," June 17, 1964.

June 18-25

At MSC, tests were completed on the modified space suit with

the new prototype helmet. Tests in the CM mockup indicated that the new helmet

gave better visibility than previous helmets. The range of nodding provided by

the neck joint, however, was not considered adequate. Both the suit and helmet

were shipped back to Hamilton Standard for additional work.

MSC, "ASPO Weekly Management Report, June 11-18, 1964"; "ASPO Weekly

Management Report, June 18-25, 1964."

June 18-25

Beech Aircraft Corporation completed qualification testing of

the hydrogen pressure vessel for the CSM electrical power system cryogenic

storage. All four vessels exceeded burst pressure specification requirements.

Two Inconel oxygen tanks also were burst tested, with satisfactory results.

MSC, "Consolidated Activity Report for the Office of the Associate

Administrator, Manned Space Flight, June 21-July 18, 1964," p. 19; MSC, "ASPO

Weekly Management Report, June 18-25, 1964."

June 18-25

MSC and Honeywell studied feasibility of the astronauts'

exercising manual control of the spacecraft during SM propulsion engine firing

to eject from earth orbit. Investigators found that, although the task became

increasingly difficult as the maneuver progressed from attitude to position

changes, manual control nonetheless was entirely feasible. North American had

studied six possible methods of providing electronic redundancy in the

stabilization and control system (SCS) to perform just this function, but in the

end recommended manual rate command. Based upon this recommendation and the

earlier study, on August 19 MSC decided to incorporate this manual rate control

capability in Block I SCS systems.

MSC, "ASPO Weekly Management Report, June 18-25, 1964"; MSC, "Consolidated

Activity Report for the Office of the Associate Administrator, Manned Space

Flight, July 19-August 22, 1964," pp. 20, 47; NAA, "Apollo Monthly Progress

Report," SID 62-300-29, October I, 1964, p. 11; interview, telephone, Kenneth J.

Cox, Houston, March 10, 1970.

June 19

Qualification testing on the launch escape motor began with a

successful static firing by the Lockheed Propulsion Company. Twenty motors were

tested during July and August; all performed satisfactorily. (See August 30.)

Lockheed Propulsion Company, "Apollo Launch Escape and Pitch Control Motors,

Monthly Progress Report No. 28," LPC No. 588-P-28, September 30, 1964, p. 5;

"Apollo Monthly Progress Report," SID 62-300-27, p. 15.

June 20

NASA announced a realignment of CSM guidance and navigation

system contractors, effective July 25. (See February 16-March 21.) Two of the

prime contractors, Kollsman Instrument Corporation (supplier of the scanning

telescope, sextant, and map and data viewer) and Raytheon Company (manufacturer

of the onboard computer), became subcontractors to AC Spark Plug, prime

contractor for the inertial measuring unit and for assembly and test of the

complete system. Under separate contracts, MIT continued to direct overall

design, development, and integration of the system, while Sperry Gyroscope

provided accelerometers. All contracts for the guidance and navigation system

were managed by MSC.

NASA News Release 64-148, "AC Spark Plug Becomes Prime Contractor for

Production of Apollo Guidance and Navigation System," June 20, 1964; MSC,

"Weekly Activity Report for the Office of the Associate Administrator, Manned

Space Flight, July 19-25, 1964," p. 3,

June 21-July 18

Two amendments to the LEM contract were forwarded to

Grumman for signature. One, for $1.257 million, was for additional flight

engineering support at MSC; the other, for $4.252 million, was for a data

acquisition system to be installed in the Apollo Propulsion System Development

Facility at WSMR.

MSC, "Consolidated Activity Report for the Office of the Associate

Administrator, Manned Space Flight, June 21-July 18, 1964," p.37; MSC News

Release 64-151, September 11, 1964,

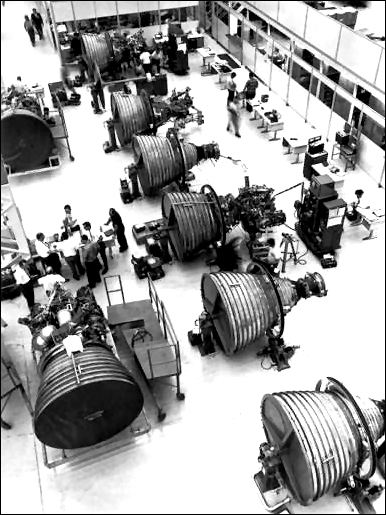

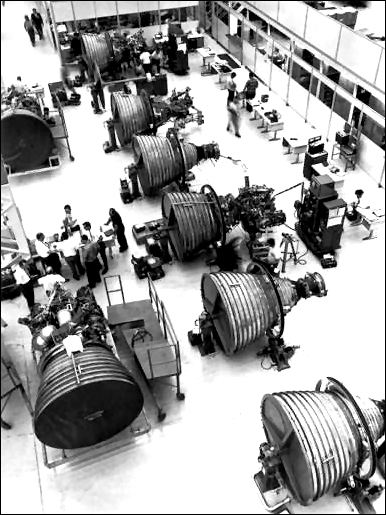

June 24

The hydrogen-fueled J-2 rocket engines for the upper stages of the

Saturn IB and Saturn V launch vehicles were completed on the assembly line at

the Canoga Park, Calif., plant of Rocketdyne Division of NAA. The J-2 developed

a thrust of 1,000 kilonewtons (225,000 pounds) at altitude. It operated in a

cluster of five engines in the S-II stage and singly in the S-IVB stage of the

Apollo launch vehicle. (Rocketdyne photo)

NASA Headquarters approved the definitive contract with Rocketdyne for the

production of 55 J-2 engines (used in the S-IVB stage of the Saturn IB and

Saturn V launch vehicles). Negotiations had taken place from April 13 to May 15.

Initial value of the contract was $89.5 million.

Akens et al., History of Marshall . . . January 1 through June

30, 1964, Vol. I, pp. 145, 226; David S. Akens, Leo L. Jones, and A. Ruth

Jarrell, History of the George C. Marshall Space Flight Center from July 1

through December 31, 1964 (MHM-10, undated), Vol. I, p. 132.

June 24

The Army Map Service reported the completion for NASA of the

first complete topographic map of the visible face of the moon.

The San Diego Union, June 25, 1964.

June 24

North American conducted the first hot fire tests of the SM

reaction control system, with steady and pulsed firings. Only one engine was

fired. The only problem encountered was with the oxidizer shutoff valve, which

would have to be completely redesigned.

MSC, "ASPO Weekly Management Report, June 25-July 2, 1964."

June 25

Grumman engineers, meeting with ASPO officials in Houston,

outlined the contractor's philosophy about onboard checkout of the LEM and

equipment required to do the job. Scheduled at times when the astronauts were

not heavily pressed with other activities, company engineers said there should

be three major checkouts of the LEM to come:

- after lunar orbit injection,

- immediately after lunar landing, and

- just before lunar launch. Of course, the astronauts would monitor the

various systems during activity with the LEM to manage and operate its

subsystems.

The contractor did not visualize any need for "centralized

onboard checkout equipment" - caution and warning lights, controls and displays,

help from the ground network, among others, should satisfy the needs. Grumman

asked MSC for authority to delete the requirement for centralized checkout

equipment, and ASPO concurred with their recommendations on July 27.

Letter, W. F. Rector III, MSC, to GAEC, Attn: R. S. Mullaney, "Contract NAS

9-1100, LEM on-board checkout equipment," July 14, 1964, with enclosure:

"Minutes of Meeting At MSC Discussing LEM On-Board Checkout Equipment, June 25,

1964"; letter, Rector to Mullaney, "Contract NAS 9-1100, LEM On-Board Checkout

Equipment," July 27, 1964.

June 25

LTV was awarded a $1,125,040 contract for a dynamic crew

procedures simulator to study task assignments in simulated space flight. The

trainer was capable of yaw, pitch, and roll movements and duplicated vibrations

and noise incurred during liftoff, powered flight, and reentry. Visual displays

simulated views of starfields, earth or moon horizons, rendezvous target

vehicles, and landscapes.

MSC News Release 64-122, July 1, 1964; MSC, "Consolidated Activity Report for

the Office of the Associate Administrator, Manned Space Flight, June 21-July 18,

1964," p. 38.

June 25-July 1

Zero g tests of the CM/LEM crew transfer tunnel were

performed in KC-135 aircraft at Wright-Patterson Air Force Base, verifying data

obtained during crew-transfer zero-g simulations conducted at North American in

February and March. The task of controlling equipment proved difficult. For

example, the docking probe was temporarily lost during removal.

MSC, "ASPO Weekly Management Report, July 2-9, 1964."

June 26

MSC awarded a letter contract (with a total cost and fee

estimated at $1.234 million) to Kollsman Instrument Corporation for optical

components for the LEM guidance and navigation system. (See October 18, 1963.)

Negotiations for a definitive contract began July 10.

MSC, "Consolidated Activity Report for the Office of the Associate

Administrator, Manned Space Flight, June 21-July 18, 1964," p. 37.

June 26

ASPO, Bellcomm, Inc., and MSC's Mission Planning and Analysis

Division completed a study on reentry range requirements. Because of the

deceleration limit of 10 g's, the minimum reentry range was 2,200 kilometers

(1,200 nautical miles [n.m.]). A range flexibility of about 1,600 kilometers

(1,000 n.m.) was essential to allow for weather conditions. An additional 1,600

kilometers (1,000 n.m.) was required by the emergency reentry monitoring system.

Therefore, the heatshield must be designed to withstand reentry heating over a

5,920-kilometer (3,200-nm.) range.

During mid-July, ASPO learned from the Landing and Recovery Division that the

minimum acceptable CM maneuverability during reentry was 1,600 kilometers (1,000

n.m.) for water landings. "This requirement was based on storm size, weather

predictability, and reliability of storm location and direction of movement."

Landing errors associated with reentry on backup guidance demanded that the

spacecraft be capable of a 6,500-kilometer (3,500-n.m.) reentry.

Memorandum, Aaron Cohen, MSC, to Owen E, Maynard, "Reentry Range

Requirement," June 26, 1964; MSC, "ASPO Weekly Management Report, July 16-23,

1964"; memorandum, Claude A. Graves, MSC, to Chief, Mission Planning and

Analysis Div., "Operational entry range requirement," June 18, 1964; memorandum,

Carl R. Huss, MSC, to BE4/Historical Office, "Comments on Volume II of The

Apollo Spacecraft: A Chronology," March 30, 1970.

June 28-July 4

MSC authorized Grumman to procure a "voice only" tape

recorder with time correlation for use in the LEM data storage electronic

assembly. The unit would be voice operated and have a capacity of 10 hours

recording time.

MSC, "Weekly Activity Report for the Office of the Associate Administrator,

Manned Space Flight, June 28-July 4, 1964," p. 3.

June 30

After acceptance testing, AiResearch Manufacturing Company

delivered the first production CM environmental control system to North

American.

The Garrett Corporation, AiResearch Manufacturing Division, "Monthly Progress

Report, Environmental Control System, NAA/S&lD, Project Apollo, 16 June

1964-15 July 1964," SS-1013-R(26), July 31, 1964, pp. 1, 15.

June 30

MSC directed North American to make whatever changes were

necessary in the Block I design to make the spacecraft compatible with the

Gemini space suit. (See May 7.)

MSC, "ASPO Weekly Management Report, June 25-July 2, 1964."

During the Month

MSC's Operations Planning Division requested OMSF to

revise its spacecraft specifications to

- delete the requirement for data storage in the LEM (this function would be

performed by the CSM data recording equipment via an RE link); and

- drop the requirement for one portable life support system (PLSS) for each

crewman (a third PLSS would only allow the CM pilot to enter the LEM without

benefit of a hard dock, and studies had shown that this situation probably

would never arise).

Early in July, MSC requested OMSF to change two

other requirements from tentative to firm:

- LEM tilt angle at lunar liftoff should not exceed 30 degrees (MSC had

accepted this value and Grumman had been asked to design systems to conform

[see May 21]);

- the service propulsion system should include a propellant control so that

unused propellants (resulting from mixture ratio shift) would not exceed 0.5

percent of the initial propellant supply. (Studies showed that the North

American design already met this requirement.)

"Apollo Quarterly Status

Report No. 8," p. 63; MSC, "ASPO Weekly Management Report, July 2-9, 1964."